XINTU’s Horizontal Wrap Around Case Packer is engineered to enhance your packaging efficiency. It automates the entire process from feeding and forming to sealing, with a packing speed of up to 12 cases per minute. This machine handles various packaging formats, including beer, liquor, beverages, dairy, condiments, soap, instant noodles, and personal care products.

Key features include precise product arrangement, high-quality hot melt glue sealing for stability, and a user-friendly PLC and touch screen control system. The versatile design adapts to different carton sizes, saving up to 20% on cardboard material compared to manual methods. Choose XINTU for a reliable, cost-effective packaging solution.

Main Features

Fast Changeover

Achieve quick changeovers with intuitive controls, minimizing downtime.

Versatile Packaging

Adapts to various carton sizes, ensuring compatibility with different products.

High Packing Speed

Packs up to 12 cases per minute, enhancing production efficiency.

Reliable Sealing

Uses high-quality hot melt glue for stable and secure sealing.

User-Friendly Interface

PLC and touch screen controls for easy operation and troubleshooting.

Durable Design

Built for long-term use in 24/7 production environments, ensuring reliability.

ADVANTAGES

Rapid packaging capacity

Packs up to 12 cases/min.

Material Efficiency

Saves 20% on carton usage.

Fast Changeovers

Changeover time is under 10 minutes.

Reliable Sealing

Uses premium hot melt glue for stability.

SPECIFICATION

Speed

Up to 12 cases per minute

Up to 720 cases per hour

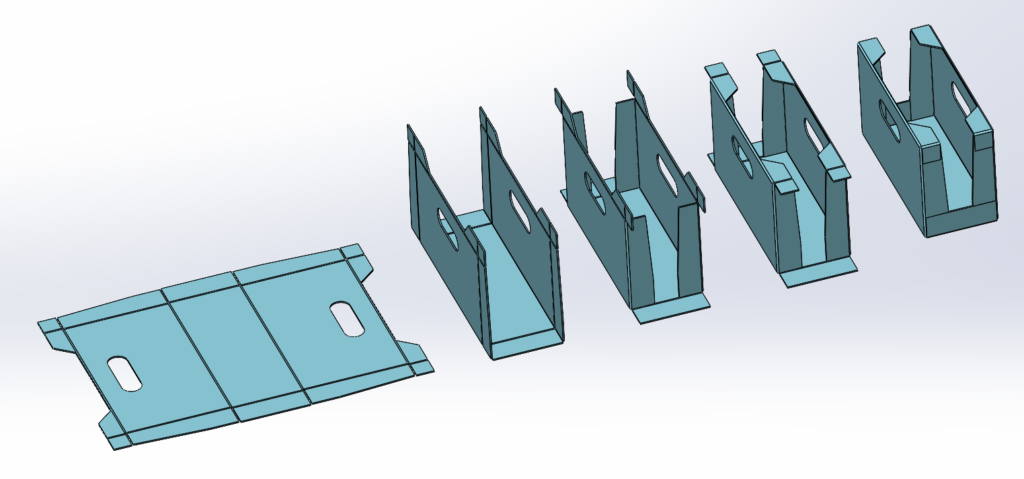

Packaging speed vary according to quantity of side push manipulators.

Case sizes

L200-500*W150-500*H100-350mm

Available to customize

Operation

Side push

Changeover

- Tool-Free Adjustment: Easily switch formats without tools in under 5 minutes.

- Automated Changeover: Utilize the HMI for seamless automatic adjustments within 3 minutes.

- Manual Adjustment: Perform simple manual changes within 10 minutes using guided instructions.

Construction

Stainless Steel

Durable, corrosion-resistant for longevity.

High-Quality Aluminum

Lightweight, strong, and resistant to wear.

Control Method

PLC + touch screen + standard control buttons + signal switch, automatic / manual control modes optional

Power Supply

380V/50Hz or 60Hz(Customized to the industrial voltage of the customer’s plant)

Air Supply

Approx. 5-6kg/㎠ 500L/min

Package Support

Bottles, Cans,Jugs,Glass bottles,Waxed paper cartons,TetraPak and Bowl packages

Case Support

One piece cardboard formed cartons

VIDEOS

Horizontal Wrap Around Case Packer For bottled dairy products

With XINTU’s Horizontal Wrap Around Case Packer, you can achieve packaging speeds of up to 12 cases per minute for bottled dairy products. This versatile machine is ideal for the dairy industry, efficiently handling various bottled products such as milk, yogurt, and cream. Its robust design ensures consistent performance and high reliability.

Horizontal Wrap Around Case Packer For bagged food

Boost your efficiency with our Drop Load Case Packer for bagged food. Packing 10-25 cartons per minute, it’s perfect for the food industry, handling products like snacks, grains, and powders. This versatile machine ensures rapid, reliable packaging, meeting your high-demand production needs effortlessly.

Horizontal Wrap Around Case Packer For bottled liquor

Enhance your production line with our Drop Load Case Packer for bottled liquor, packing 10-25 cartons per minute. Designed for the beverage industry, it handles various bottle sizes and shapes, ensuring consistent, high-volume packaging. Ideal for liquor, wine, and spirits, this machine guarantees efficient, reliable operation to meet your demanding production schedules.

LAYOUT DRAWINGS

Explore our extensive range of Packaging layout solutions tailored for your project needs.

Layout of Horizontal Wrap Around Case Packer

12 cases per minute case packer layout for beverage plants

RELATED EQUIPMENT

Integrated packaging line solutions

Add Your Heading Text Here

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Add Your Heading Text Here

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Add Your Heading Text Here

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

FAQ

Listed below are the types of technical questions you may have about XINTU Horizontal Wrap Around Case Packing Machine

Working Principles of XINTU Horizontal Wrap Around case packaging machine

The XINTU Horizontal Wrap Around Case Packer is a high-performance packaging solution designed to streamline end-of-line operations. Here’s how it works:

Product Feeding:

- Products are fed horizontally into the Horizontal Case Packer. This Horizontal Packaging Machine aligns products in a consistent orientation, ensuring smooth downstream processing.

Carton Formation:

- Utilizing a single sheet of corrugated material, the Wrap Around Case Packer forms a carton around the product. This method reduces material usage and provides a secure packaging solution.

Automatic Operation:

- The entire process, from product feeding to carton sealing, is automated. This Automatic Case Packer minimizes manual intervention, boosting productivity and reducing labor costs.

High-Speed Packaging:

- Designed for high-speed operations, the High-Speed Case Packer can handle a large number of products per minute, meeting the demands of fast-paced production environments.

Wrap Around Carton Packing:

- The machine wraps the carton tightly around the products, ensuring stability and protection during transportation. The Wrap Around Carton Packer is ideal for various product shapes and sizes.

End-of-Line Efficiency:

- As an End-of-Line Packaging Machine, it handles the final packaging steps, preparing products for shipment or retail display efficiently.

Horizontal Case Packing System:

- This system is optimized for a variety of product types, offering flexible and adaptable packaging solutions. The Horizontal Case Packing System integrates seamlessly with existing production lines.

Versatile Carton Packing:

- Capable of handling different carton sizes and shapes, this Carton Packing Machine meets diverse packaging requirements across industries.

Automated Precision:

- The Automated Case Packing Equipment uses advanced automation technology to ensure consistent performance, reduced downtime, and minimal maintenance needs.

By integrating these advanced features, the XINTU Horizontal Wrap Around Case Packer provides a reliable and efficient packaging solution that enhances productivity and ensures high-quality packaging outcomes.

Maintenance of Your XINTU Horizontal Wrap Around Case Packer

Regular maintenance of your XINTU Horizontal Wrap Around Case Packer is crucial to ensure optimal performance and longevity. Here’s a guide to help you maintain your equipment efficiently:

Routine Inspections:

- Conduct regular visual inspections of the Horizontal Case Packer to identify any signs of wear and tear or potential issues. Check for loose bolts, damaged parts, and ensure all moving components are functioning smoothly.

Lubrication:

- Ensure that all moving parts of the Wrap Around Case Packer are properly lubricated. Regular lubrication minimizes friction, reduces wear, and extends the life of the machine. Follow the manufacturer’s guidelines for the appropriate lubricants and frequency.

Cleaning:

- Keep the Automatic Case Packer clean to prevent dust and debris from affecting its operation. Regular cleaning helps maintain the efficiency of the Horizontal Packaging Machine and prevents contamination of products.

Calibration:

- Periodically calibrate the High-Speed Case Packer to maintain accuracy in packaging. Proper calibration ensures that the machine operates at optimal speeds and that the cartons are packed consistently.

Component Replacement:

- Replace worn-out components of the Wrap Around Carton Packer promptly. Keeping spare parts on hand can minimize downtime and keep the End-of-Line Packaging Machine running smoothly.

Software Updates:

- Ensure that the software for the Horizontal Case Packing System is up-to-date. Regular updates can provide new features, improve performance, and fix any existing bugs in the Carton Packing Machine.

Operator Training:

- Train your staff regularly on the best practices for operating and maintaining the Automated Case Packing Equipment. Proper training can help prevent misuse and extend the lifespan of the machine.

Documentation:

- Maintain detailed records of all maintenance activities. This documentation can help track the performance of the machine and identify any recurring issues.

By following these maintenance tips, you can ensure that your XINTU Horizontal Wrap Around Case Packer continues to operate efficiently, providing reliable and high-speed packaging solutions for your production line. Regular maintenance not only enhances the performance of your equipment but also extends its operational life, ensuring consistent and high-quality packaging outcomes.

The XINTU Horizontal Wrap Around Case Packaging Machine leverages advanced technology to ensure efficient and reliable packaging solutions. Here are the key technological aspects integrated into this cutting-edge equipment:

Automation Excellence:

- As an Automatic Case Packer, this machine is designed to streamline the packaging process, reducing the need for manual intervention and increasing throughput. The automation capabilities ensure consistent performance and reliability.

High-Speed Operation:

- The High-Speed Case Packer is capable of handling large volumes of products swiftly. This efficiency is essential for high-demand production environments, ensuring that packaging lines keep pace with production rates.

Precision Engineering:

- The Horizontal Case Packer features precision engineering that guarantees accurate case formation and sealing. This precision minimizes product damage and ensures that each package meets the highest quality standards.

Versatile Packaging Solutions:

- This machine excels in handling a variety of packaging formats. Whether you need a Wrap Around Carton Packer or a Horizontal Packaging Machine, the flexibility of the system allows it to adapt to different product sizes and shapes.

End-of-Line Integration:

- The XINTU machine is designed as an End-of-Line Packaging Machine, seamlessly integrating with existing production lines. This Horizontal Case Packing System ensures smooth transitions and minimizes bottlenecks in the production process.

Advanced Control Systems:

- Equipped with state-of-the-art control systems, the Carton Packing Machine provides real-time monitoring and diagnostics. These features help in maintaining optimal performance and quickly addressing any issues that arise.

User-Friendly Interface:

- The Automated Case Packing Equipment comes with an intuitive user interface, making it easy for operators to manage the machine. The interface provides clear instructions and feedback, enhancing operational efficiency.

Durable Construction:

- Built with robust materials, the Vertical Wrap Around Case Packer and the Gravity Feed Case Packer variants ensure long-term durability and reliability, even in demanding industrial environments.

Environmental Adaptability:

- The technology allows the machine to operate effectively in various environmental conditions, making it suitable for a wide range of industries and applications.

By incorporating these technological advancements, the XINTU Horizontal Wrap Around Case Packaging Machine offers a comprehensive and efficient solution for modern packaging needs, ensuring high-speed, reliable, and flexible operations across various production lines.

Step-by-Step Installation Process

1. Site Preparation

Ensure that the installation site is clean, level, and free from obstructions. Verify that all necessary utilities such as electrical supply and compressed air are readily available and properly installed.

2. Unpacking and Inspection

Carefully unpack the machine and inspect all components for any damage that may have occurred during shipping. Verify that all parts are included as per the packing list.

3. Positioning the Machine

Move the XINTU Side Entry Wrap-Around Case Packaging Machine to its designated location. Ensure that the machine is positioned correctly according to the site layout plan, leaving sufficient space for operation and maintenance.

4. Electrical Connections

Connect the machine to the electrical supply according to the specifications provided in the manual. Ensure that all electrical connections are secure and comply with local electrical codes.

5. Air Supply Connection

Connect the machine to the compressed air supply. Ensure that the air pressure meets the machine’s requirements as specified in the manual. Check for any air leaks and fix them as necessary.

6. Alignment and Leveling

Level the machine using adjustable feet to ensure it is stable and properly aligned. Use a spirit level to check for accuracy and make adjustments as needed.

7. Assembling Components

Assemble any additional components or modules that may have been shipped separately. Follow the instructions provided in the installation manual for proper assembly.

8. Calibration and Setup

Calibrate the machine settings according to the product and packaging specifications. Input the necessary parameters into the PLC and touch screen interface for optimal performance.

9. Testing and Verification

Run a series of test cycles to verify the machine’s operation. Check for proper case formation, product loading, and sealing. Make any necessary adjustments to ensure optimal performance.

10. Operator Training

Provide comprehensive training to the operators on how to use and maintain the machine. Ensure they understand the safety protocols, operational procedures, and troubleshooting techniques.

11. Final Inspection and Handover

Conduct a final inspection to ensure the machine is installed correctly and operating efficiently. Hand over the machine to the production team with all necessary documentation and user manuals.

By following these detailed installation steps, you can ensure that your XINTU Side Entry Wrap-Around Case Packaging Machine is set up correctly, maximizing its efficiency and reliability.

Yes, the XINTU Side Entry Wrap-Around Case Packaging Machine is designed to handle a wide range of product sizes and shapes. Its versatile design allows for easy adjustments and configurations to accommodate various packaging needs. Whether you are dealing with bottles, cans, cartons, or irregularly shaped products, this machine ensures precise and efficient packaging.

Key Features for Versatility:

- Adjustable Settings: The machine features adjustable guides and components that can be quickly modified to fit different product dimensions and shapes.

- Customizable Pack Patterns: You can easily configure the pack patterns to suit specific requirements, whether it’s vertical, horizontal, or custom orientations.

- Automated Adjustments: Equipped with advanced automation and PLC control, the machine can automatically adjust settings for different product runs, minimizing downtime and ensuring consistent performance.

- Flexible Material Handling: Designed to handle various packaging materials, including cardboard and plastic, ensuring secure and stable packaging for a diverse range of products.

By integrating these features, the XINTU Side Entry Wrap-Around Case Packaging Machine provides a flexible and reliable solution for diverse packaging needs, enhancing your production efficiency and adaptability.

Types of Side Entry Wrap-Around Case Packers

There are several types of side entry wrap-around case packers, each designed to meet specific packaging needs and industry requirements. Here are the main types:

Standard Side Entry Wrap-Around Case Packer:

- Features: Basic model with standard side entry loading.

- Applications: Suitable for various product types such as bottles, cans, and cartons.

- Industry: Food and beverage, personal care, household products.

High-Speed Side Entry Wrap-Around Case Packer:

- Features: Enhanced speed capabilities, often with additional automation features.

- Applications: High-volume packaging operations.

- Industry: Beverage, dairy, and other high-throughput industries.

Robotic Side Entry Wrap-Around Case Packer:

- Features: Incorporates robotic arms for precise and flexible handling.

- Applications: Complex packaging tasks, products with irregular shapes.

- Industry: Pharmaceuticals, electronics, and specialized products.

Compact Side Entry Wrap-Around Case Packer:

- Features: Smaller footprint, designed for limited space environments.

- Applications: Small to medium-sized operations.

- Industry: Small-scale food producers, boutique manufacturers.

Heavy-Duty Side Entry Wrap-Around Case Packer:

- Features: Built to handle heavier products and larger cases.

- Applications: Industrial products, large bottles or cans.

- Industry: Chemical, automotive, and industrial goods.

Each type of side entry wrap-around case packer is tailored to optimize performance for specific packaging challenges, ensuring efficiency, flexibility, and reliability in various industrial settings.

Efficiency Benefits of Using the XINTU Side Entry Wrap-Around Case Packer

Increased Throughput:

- The XINTU Side Entry Wrap-Around Case Packer is designed to handle high-speed packaging operations, achieving speeds of up to 12 cases per minute. This high throughput reduces production time and increases overall productivity.

Flexible Packaging Solutions:

- This machine is capable of handling various product sizes and shapes, accommodating different packaging needs without the need for extensive reconfiguration. This flexibility allows for quick changeovers, minimizing downtime and maintaining efficiency.

Material Savings:

- By using a single sheet of cardboard to wrap around products, this case packer reduces the need for pre-made boxes, saving on material costs and storage space. This efficiency in material usage also contributes to a more sustainable packaging process.

Reduced Labor Costs:

- Automation of the packing process significantly reduces the need for manual labor. With features like automated feeding, forming, and sealing, the XINTU Side Entry Wrap-Around Case Packer streamlines operations and lowers labor costs.

Enhanced Product Protection:

- The precision and consistency of the machine ensure that each product is securely packed, reducing the risk of damage during transit. This reliability in packaging enhances product safety and quality, leading to fewer returns and customer complaints.

Advanced Control Systems:

- Equipped with a PLC control system and touch screen interface, the machine offers easy operation and real-time monitoring. This advanced technology allows for quick adjustments and diagnostics, further enhancing operational efficiency.

By integrating these efficiency benefits, the XINTU Side Entry Wrap-Around Case Packaging provides a comprehensive solution to meet the diverse and demanding needs of modern packaging operations.

Main Features of XINTU Side Entry Wrap Around Case Packing machine

Advanced Control System:

- Utilizes a PLC control system and touch screen interface for precise operation and easy monitoring.

Efficient Changeovers:

- Features an advanced HMI with intuitive navigation, quick-release handles, and interactive changeover guides, allowing technicians to complete changeovers in under 5 minutes.

Versatile Packaging:

- Capable of handling various product sizes and shapes, accommodating different packaging requirements seamlessly.

High-Speed Operation:

- Can achieve packing speeds of up to 12 cases per minute, ensuring high productivity.

Durable Construction:

- Built with robust materials optimized for 24/7 operation, ensuring long-term durability and reliability.

Enhanced Safety Features:

- Includes highly reliable non-contact interlocks and CAT-3 safety circuits to ensure safe and efficient operation.

Remote Access Capability:

- Equipped with remote access for efficient troubleshooting and maintenance without the need for in-person visits.

Precise Product Handling:

- Features advanced sensors and vision systems to ensure precise alignment and placement of products, minimizing errors.

Energy Efficient:

- Uses high-quality hot melt glue systems to ensure stable sealing while being energy efficient and reducing operational costs.

Flexible Configuration:

- Easily adjustable settings allow for quick adaptation to various packaging needs, making it suitable for a wide range of industries including beverages, dairy, and consumer goods.

These features collectively make the XINTU Side Entry Wrap Around Case Packer a reliable and versatile solution for efficient and high-quality packaging operations.

Ensuring Consistent Packing with the XINTU Side Entry Wrap Around Case Packer

To ensure consistent packing, the XINTU Side Entry Wrap Around Case Packing machine employs several advanced features and technologies:

Advanced Control Systems:

- The machine is equipped with a PLC control system and touch screen interface, which allows for precise control and monitoring of the packing process. This ensures that each product is packed accurately and consistently.

High-Quality Sensors:

- The use of high-quality sensors and vision systems ensures that products are correctly aligned and placed within the case. This minimizes errors and ensures uniform packing.

Adjustable Settings:

- The machine's settings can be easily adjusted to accommodate different product sizes and shapes. This flexibility ensures that products are consistently packed regardless of variations in product dimensions.

Reliable Mechanisms:

- The machine features reliable non-contact interlocks and safety redundancies that prevent disruptions in the packing process. This reliability contributes to consistent packing output.

Fast and Efficient Changeovers:

- The advanced HMI with intuitive navigation and quick-release handles allows for fast changeovers, reducing downtime and maintaining a steady packing process. Technicians can perform changeovers in under 5 minutes, ensuring minimal disruption.

Robust Design:

- Built with durable materials, the machine is optimized for long-term use in a 24/7 production environment. This robustness ensures consistent performance over time.

These features collectively ensure that the XINTU Side Entry Wrap Around Case Packaging machine delivers reliable and consistent packing results, enhancing your production efficiency and product quality.

Integrating the XINTU Side Entry Wrap Around Case Packer into an Existing Production Line

Integrating the XINTU Side Entry Wrap Around Case Packing machine into your existing production line can enhance efficiency and streamline your packaging process. Here's how you can achieve a seamless integration:

Assessment and Planning:

- Conduct a comprehensive assessment of your current production line to identify potential integration points.

- Plan the layout considering the space, workflow, and positioning of the case packer to ensure optimal efficiency.

Customization and Configuration:

- Customize the case packer settings to match the specifications and requirements of your existing production line.

- Configure the machine's software to synchronize with other equipment in the line, ensuring smooth operation.

Mechanical Integration:

- Connect the case packer to your existing conveyor systems to facilitate the seamless transfer of products.

- Ensure proper alignment and positioning of the packer relative to other machinery to avoid disruptions in the workflow.

Electrical and Control Systems Integration:

- Integrate the packer’s PLC control system with your line's central control system for unified operation.

- Set up communication protocols to enable data exchange and synchronization between the case packer and other line components.

Testing and Validation:

- Conduct thorough testing of the integrated system to identify and rectify any issues.

- Validate the performance of the case packer within the production line to ensure it meets the desired efficiency and quality standards.

Training and Support:

- Provide training for your operators and maintenance staff on the operation and troubleshooting of the case packer.

- Utilize XINTU's remote access capability for ongoing support and maintenance, minimizing downtime and ensuring continuous operation.

By following these steps, you can effectively integrate the XINTU Side Entry Wrap Around Case Packaging system into your existing production line, enhancing productivity and ensuring consistent, high-quality packaging.

Production Capacity of Different Models of XINTU Side Entry Wrap Around Case Packers

The production capacity of XINTU Side Entry Wrap Around Case Packers varies depending on the specific model and configuration. Here is a summary of the production capacities for different models:

Standard Model:

- Capacity: Up to 12 cases per minute

- Suitable for: Moderate-speed production lines, ideal for small to medium-sized operations.

High-Speed Model:

- Capacity: Up to 20 cases per minute

- Suitable for: High-speed production environments requiring efficient handling of large volumes.

Customized Model:

- Capacity: Customizable based on specific production requirements.

- Suitable for: Specialized applications where production capacity needs to be tailored to unique operational demands.

Advanced Automation Model:

- Capacity: Up to 30 cases per minute

- Suitable for: Large-scale manufacturing facilities that need to maximize throughput while maintaining high precision and consistency.

Factors Affecting Production Capacity

Product Size and Shape:

- The capacity can vary based on the size and shape of the products being packed. Smaller, uniform products generally allow for higher throughput.

Packaging Material:

- The type of packaging material used (e.g., corrugated boxes, cartons) can impact the machine's efficiency and speed.

Integration with Other Equipment:

- Seamless integration with upstream and downstream equipment can enhance overall line efficiency and increase production capacity.

Advantages

- Efficiency: High-speed models can significantly boost production output.

- Customization: Models can be tailored to specific production needs, ensuring optimal performance.

- Flexibility: Capable of handling a wide range of product sizes and shapes, adapting to various packaging requirements.

These capacities are indicative and can be further customized based on the specific needs of your production line. For detailed specifications and customization options, please contact XINTU directly.

Enhancing the efficiency of your Side Entry Wrap Around Case Packaging machine involves implementing several best practices and advanced technologies. This approach ensures that your automated packaging machine operates at peak performance within your case packing system.

Regular Maintenance and Calibration

Automated Packaging Machine:

- Routine Maintenance: Regularly inspect and maintain all components to prevent downtime. Lubricate moving parts and clean the equipment as per the maintenance schedule.

- Precision Calibration: Ensure sensors and alignment mechanisms are calibrated correctly to avoid packing errors and maintain efficiency.

Integration of Advanced Technologies

Case Packing System:

- Vision Systems: Integrate vision systems to enhance accuracy in product placement and identify defects early.

- Line Tracking: Utilize line tracking technology to synchronize with upstream and downstream equipment, ensuring a smooth product flow.

Workflow and Layout Optimization

Secondary Packaging Equipment:

- Ergonomic Design: Design the layout of your packing line to minimize movement and streamline operations.

- Automated Handling: Employ automated conveyors and handling systems to reduce manual intervention and increase throughput.

Continuous Training and Performance Monitoring

Carton Packing Line:

- Operator Training: Provide continuous training to operators on best practices and new features of the equipment.

- Performance Monitoring: Regularly monitor performance metrics and adjust settings to maintain optimal efficiency.

Investment in Quality Materials

Industrial Case Packer:

- Consistent Materials: Use high-quality, consistent packaging materials to reduce downtime caused by jams or malfunctions.

- Reliable Suppliers: Maintain strong relationships with suppliers to ensure a steady supply of materials that meet specifications.

Implementation of High-Speed Solutions

High-Speed Packaging Solutions:

- Component Upgrades: Invest in high-speed components to boost the overall speed of the packing process.

- Software Updates: Keep the software updated to utilize the latest efficiency features and improvements.

By adopting these strategies, you can significantly improve the efficiency and performance of your Side Entry Wrap Around Case Packer, ensuring it operates effectively within your automated packaging machine system. This comprehensive approach not only enhances the case packing system but also optimizes the entire secondary packaging process, contributing to the overall success of your carton packing line.

When operating a Side Entry Wrap Around Case Packer, several common issues may arise. Addressing these problems promptly can maintain the efficiency and reliability of your automatic case packer, ensuring optimal performance of your end-of-line packaging solutions.

1. Misalignment of Products

Issue: Products are not properly aligned, leading to packing errors. Troubleshooting:

- Regular Calibration: Ensure that the sensors and alignment mechanisms are regularly calibrated.

- Vision Systems: Utilize vision systems to detect and correct misalignments in real-time.

2. Jamming in the Carton Packing Machine

Issue: The machine experiences frequent jams, causing downtime. Troubleshooting:

- Routine Cleaning: Perform routine cleaning to remove debris that may cause jamming.

- Quality Materials: Use consistent, high-quality packaging materials to minimize the risk of jams.

3. Inconsistent Sealing

Issue: Cases are not being sealed properly, resulting in product damage or contamination. Troubleshooting:

- Seal Inspection: Regularly inspect and maintain the sealing components.

- Proper Settings: Ensure that the temperature and pressure settings for the sealing process are correctly configured.

4. Reduced Speed and Efficiency

Issue: The automatic case packer is not operating at the desired speed, affecting production throughput. Troubleshooting:

- Maintenance: Conduct regular maintenance to ensure all components are functioning correctly.

- Software Updates: Keep the machine’s software updated to take advantage of the latest efficiency improvements.

- Component Upgrades: Invest in high-speed components to enhance performance.

5. Sensor Malfunctions

Issue: Sensors are not detecting products accurately, leading to operational issues. Troubleshooting:

- Sensor Calibration: Regularly calibrate sensors to ensure accurate detection.

- Sensor Cleaning: Clean sensors to remove dust and debris that may affect their performance.

6. Mechanical Wear and Tear

Issue: Wear and tear on mechanical parts lead to frequent breakdowns. Troubleshooting:

- Preventive Maintenance: Implement a preventive maintenance schedule to replace worn-out parts before they fail.

- Quality Components: Use high-quality components to extend the lifespan of the case packing equipment.

7. Inconsistent Product Handling

Issue: Variability in product handling leads to inconsistent packing quality. Troubleshooting:

- Standardize Processes: Standardize the handling processes to ensure consistency.

- Training: Provide comprehensive training to operators to handle products uniformly.

8. Control System Errors

Issue: The control system experiences errors, disrupting the packing process. Troubleshooting:

- System Diagnostics: Run regular diagnostics on the control system to identify and fix errors.

- Firmware Updates: Ensure the control system firmware is up-to-date to prevent compatibility issues.

By addressing these common issues, you can ensure your high-speed case packer operates efficiently, maintaining the integrity of your carton packing machine and overall case packing equipment. This proactive approach will enhance the reliability and performance of your end-of-line packaging solutions.

Energy Requirements for Operating the XINTU Side Entry Wrap Around Case Packer

Operating the XINTU Side Entry Wrap Around Case Packer involves specific energy requirements to ensure its efficiency and effectiveness in your packaging line. This automatic case packer is designed for optimal performance in end-of-line packaging solutions, offering high-speed case packing capabilities for various applications.

Electrical Power

- Voltage: The machine typically requires a 3-phase electrical supply with a voltage of 380V.

- Frequency: Operates at a standard frequency of 50/60 Hz.

- Power Consumption: The case packing equipment consumes approximately 10KW of power during operation.

Compressed Air

- Pressure Requirement: The carton packing machine requires a consistent air pressure of 0.5-0.7 MPa to function effectively.

- Air Consumption: The high-speed case packer utilizes around 500-700 liters of compressed air per minute.

Operational Efficiency

- Energy Optimization: The XINTU Side Entry Wrap Around Case Packer is equipped with energy-efficient components that minimize power consumption while maintaining high performance. The machine’s design ensures that energy use is optimized, reducing operational costs.

- Automation Benefits: As an automated case packer, it incorporates advanced technologies that further enhance energy efficiency. Features like automated changeover, intelligent control systems, and high-speed servo motors contribute to lower energy consumption.

Integration and Compatibility

- End-of-Line Integration: The XINTU Side Entry Wrap Around Case Packer integrates seamlessly with other end-of-line packaging solutions, such as palletizers and conveyors, to create a cohesive and energy-efficient packaging line.

- High-Speed Capabilities: Designed as a high-speed case packer, it can handle various product sizes and shapes, maintaining efficiency without compromising on energy consumption.

By understanding and managing the energy requirements of the XINTU Side Entry Wrap Around Case Packer, you can optimize your production line for both performance and cost-effectiveness. This case packing equipment ensures reliable and efficient packaging solutions, meeting the demands of modern industrial environments.

Safety Features of the XINTU Side Entry Wrap Around Case Packer

The XINTU Side Entry Wrap Around Case Packer is an advanced automated packaging machine designed to ensure both high performance and safety. It incorporates several safety features to protect operators and maintain efficient operation within your case packing system. Below are the key safety features integrated into this industrial case packer, ideal for secondary packaging equipment in any carton packing line:

Safety Features:

1. Emergency Stop Buttons

- Strategically placed emergency stop buttons provide immediate shutdown capabilities in case of emergencies, ensuring quick response to any potential hazards.

2. Safety Light Curtains

- Advanced safety light curtains create a protective barrier around the operational area, stopping the machine instantly if the barrier is breached to prevent accidents.

3. Safety Interlocks

- Highly reliable non-contact safety interlocks ensure that access doors cannot be opened while the machine is in operation, preventing unintended access to moving parts.

4. CAT-3 Safety Circuits

- The machine is equipped with Category 3 (CAT-3) safety circuits that offer redundancy and reliability, ensuring continuous safe operation even in the event of a component failure.

5. High-Visibility Machine Status Lighting

- The machine features high-visibility status lighting to provide clear, real-time indicators of machine status, helping operators quickly identify and respond to any issues.

6. Guarding and Protective Enclosures

- Robust guarding and protective enclosures around moving parts minimize the risk of injury, ensuring that operators are protected from mechanical hazards.

Integration and Automation Benefits

- Automated Packaging Machine: Enhances operational safety with automated processes, reducing the need for manual intervention and associated risks.

- Case Packing System: Integrates seamlessly into your existing carton packing line, maintaining high safety standards across the entire secondary packaging equipment setup.

- Industrial Case Packer: Designed for industrial environments, ensuring robust safety features suitable for high-speed packaging solutions.

By incorporating these comprehensive safety features, the XINTU Side Entry Wrap Around Case Packer not only optimizes efficiency but also prioritizes the well-being of operators, making it a reliable choice for your automated packaging needs.

Selecting the appropriate Side Entry Wrap Around Case Packer for your packaging operations is crucial for ensuring efficiency and meeting production goals. Here’s a guide to help you choose the right machine tailored to your needs, focusing on key aspects of automated packaging machines and high-speed packaging solutions.

1. Assess Your Product Specifications

Evaluate Product Dimensions and Shapes

- Determine the range of product sizes and shapes you need to pack. Ensure the case packer can accommodate these variations seamlessly within your carton packing line.

Consider Product Weight

- Identify the weight of your products to select a machine that can handle them efficiently without compromising the packing speed.

2. Determine Packaging Speed Requirements

High-Speed Packaging Solutions

- Calculate your required throughput to match a case packer with the necessary speed. High-speed packaging solutions should meet your production rates to maintain efficiency.

Consistency and Reliability

- Look for an industrial case packer that offers consistent performance and minimal downtime to keep your production line running smoothly.

3. Evaluate Integration Capabilities

Automated Packaging Machine Integration

- Ensure the case packer can integrate seamlessly with your existing automated packaging machines, enhancing your overall case packing system.

Compatibility with Secondary Packaging Equipment

- The machine should work well with other secondary packaging equipment in your production line to streamline operations.

4. Review Technical Features and Specifications

Advanced Technologies

- Opt for a case packer equipped with advanced technologies such as vision systems, line tracking, and robotic arms for precise handling and placement.

Customization Options

- Consider machines that offer customization to meet specific packaging requirements, ensuring flexibility for various products and pack patterns.

5. Check for Ease of Use and Maintenance

User-Friendly Interface

- Choose a machine with an intuitive human-machine interface (HMI) to facilitate easy operation and quick troubleshooting.

Maintenance and Support

- Ensure the machine is designed for easy maintenance and comes with reliable technical support to minimize downtime.

6. Consider Safety Features

Comprehensive Safety Systems

- Prioritize machines with robust safety features, such as safety light curtains, emergency stop buttons, and non-contact interlocks, to ensure operator safety and machine longevity.

Conclusion

Selecting the right Side Entry Wrap Around Case Packer involves evaluating your product specifications, packaging speed requirements, integration capabilities, technical features, ease of use, and safety features. By carefully considering these factors, you can choose an automated packaging machine that enhances your case packing system and meets your production needs efficiently.

Choosing the right Side Entry Wrap Around Case Packer can significantly boost your productivity and ensure seamless operations in your carton packing line, providing a reliable and efficient solution for your industrial packaging requirements.

Ensuring that your team is well-trained to operate a Side Entry Wrap Around Case Packer safely is essential for maintaining productivity and reducing the risk of accidents. Here’s a comprehensive guide to training your staff effectively, focusing on key aspects of automated packaging machines, case packing systems, and high-speed packaging solutions.

1. Comprehensive Training Program

Develop a Structured Curriculum

- Create a detailed training program that covers all aspects of the Side Entry Wrap Around Case Packer, including its role in the carton packing line and integration with other secondary packaging equipment.

Hands-On Training Sessions

- Conduct practical, hands-on training sessions where operators can interact directly with the industrial case packer under supervision.

2. Safety Protocols and Procedures

Emphasize Safety Features

- Teach staff about the machine’s safety features, such as safety light curtains, emergency stop buttons, and non-contact interlocks. Ensure they understand how to use these features effectively.

Standard Operating Procedures (SOPs)

- Provide clear SOPs for operating the case packing system. Ensure these procedures include steps for startup, normal operation, and shutdown.

3. Understanding the Technology

Automated Packaging Machine Components

- Explain the key components of the automated packaging machine, including sensors, actuators, and the human-machine interface (HMI).

Advanced Features

- Train staff on using advanced features such as vision systems and line tracking to maximize efficiency and ensure precise packing.

4. Regular Maintenance and Troubleshooting

Routine Maintenance Tasks

- Educate operators on routine maintenance tasks that are crucial for the machine’s longevity and consistent performance.

Troubleshooting Techniques

- Provide troubleshooting guides and practical training on how to identify and resolve common issues with the case packing equipment.

5. Continuous Improvement and Updates

Ongoing Training

- Implement a schedule for ongoing training sessions to keep staff updated on new features or changes in the case packing system.

Feedback Mechanism

- Establish a feedback mechanism where operators can report issues and suggest improvements for the training program.

Conclusion

By implementing a comprehensive training program that emphasizes safety, understanding of technology, regular maintenance, and continuous improvement, you can ensure that your staff operates the Side Entry Wrap Around Case Packer safely and efficiently. This approach not only enhances productivity but also ensures the smooth operation of your carton packing line and overall case packing system.

Providing detailed and continuous training on high-speed packaging solutions is essential for maximizing the benefits of your automated packaging machine and ensuring a safe working environment.

Latest Technological Advancements in Side Entry Wrap Around Case Packer

The Side Entry Wrap Around Case Packer has seen significant technological advancements, enhancing its efficiency and versatility in the packaging industry. Here are some of the latest innovations in this automated packaging machine, focusing on improvements in case packing systems, secondary packaging equipment, and high-speed packaging solutions.

1. Advanced Automation and Robotics

Robotic Integration

- Modern side entry wrap-around case packers now incorporate advanced robotics to handle a variety of packaging formats with high precision. These robots enable faster and more flexible packing, making the machine suitable for various carton packing lines.

Vision Systems

- Enhanced vision systems allow for real-time inspection and correction of product alignment, ensuring that each item is perfectly placed within the case. This reduces errors and increases the overall efficiency of the case packing system.

2. High-Speed Packaging Solutions

Increased Throughput

- With the integration of high-speed components, these industrial case packers can now achieve packing speeds previously unattainable. This results in a significant boost in production capacity, meeting the demands of high-volume production environments.

Optimized Motion Control

- Advanced motion control technologies ensure smooth and rapid movements of the packing elements, minimizing downtime and maximizing productivity. This is crucial for maintaining a continuous flow in high-speed packaging solutions.

3. Enhanced Flexibility and Adaptability

Multi-Format Capability

- The latest models can handle multiple packaging formats, including different sizes and shapes of products and cartons. This adaptability is essential for industries with diverse product lines, ensuring seamless integration into existing carton packing lines.

Quick Changeover Systems

- Innovative quick changeover systems allow for rapid transitions between different packaging runs, reducing downtime and increasing overall efficiency. This is particularly beneficial in environments where product variety is high.

4. Improved User Interface and Control Systems

Intuitive HMI

- The human-machine interface (HMI) has been upgraded to provide a more intuitive and user-friendly experience. Operators can easily navigate the system, perform diagnostics, and make adjustments, ensuring smooth operation of the secondary packaging equipment.

Remote Monitoring and Control

- Remote access capabilities allow for real-time monitoring and control of the packaging machine, enabling quick response to any issues and minimizing downtime. This feature is crucial for maintaining high operational efficiency.

Conclusion

The technological advancements in Side Entry Wrap Around Case Packers have significantly improved their functionality, efficiency, and adaptability. By incorporating advanced automation, high-speed solutions, enhanced flexibility, and improved control systems, these automated packaging machines are better equipped to meet the diverse needs of modern production lines. Integrating these innovations ensures that your case packing system remains at the forefront of the industry, delivering reliable and efficient performance.