When it comes to elevating your packaging process, XINTU’s Vertical Automatic Case Erector Machine VCE01 sets the standard.

Designed to accommodate a diverse range of case applications and corrugate variances, our Case Erectors utilize dual opposing vacuum systems and advanced flap control to ensure flawless case formation. The servo-driven flights maintain the perfect squareness of the case as it progresses through the machine. With its compact footprint and sliding doors, this Automatic Box Erector seamlessly fits into challenging spaces. Equipped with a user-friendly interface, our Carton Erectors streamline operations and maximize efficiency. Choose XINTU for cutting-edge Packaging Automation that transforms your production line.

SPECIFICATION

Speed

Up to 10-12 cases per minute

Up to 600-720 cases per hour

Packaging speed vary according to case/carton sizes.

Case sizes

L250-450×W150-400×H100-400mm(Can be customized)

Carton Storage Quantity

80-100pcs (800-1000mm)

Adhesive Tape Width

48/60/75mm (optional)

Changeover

- Tool-Free Adjustment: Adjust box dimensions in under 5 minutes by hand wheels for sizes L250-450×W150-400×H100-400mm.

- Quick-Release System: Switch between carton sizes in 3 minutes with our quick-release mechanism.

- Preset Configurations:Utilize up to 5 preset carton settings for fast changeovers in less than 2 minutes.

Control Method

PLC + touch screen + standard control buttons + signal switch, automatic / manual control modes optional

Power Supply

220V 50/60Hz 1 Phase(Customized to the industrial voltage of the customer’s plant)

Consumption: 240W

Air Supply

450NL/min

6kg/cm³

Case Support

Standard Regular Slotted Containers (RSC)/Half Slotted Containers (HSC)/Full Overlap Slotted Containers (FOL)

Main Features

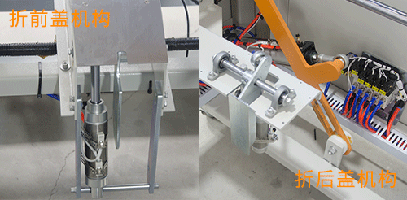

Mechanism of folding front and rear board

Upgraded mechanism of folding front and rear board, cartons can be formed faster, stable and endurable.

Replace tape quickly

Equipped with protective door, replacing tape conveniently and safely as the door open.

Push carton board automatic buckle

Material trough fixed bracket with push carton board automatic buckle, lock material trough which is convenient for user.

Siemens or Inovance PLC

The internal electric circuit adopts anti-jamming technology and Siemens control program, which can control position accurately and work stable for long time.

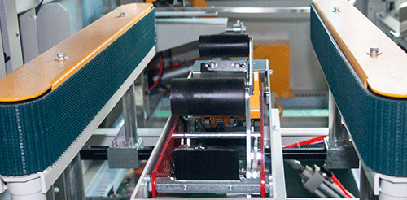

Endurable conveyor belt

Using endurable conveyor belt with strong friction which can transport steadily.

Available for multiple-size cartons

Width can be as small as 150mm

ADVANTAGES

Fast Operation

Up to 12 cases/min

Compact Design

Fits in spaces as small as 2m², perfect for tight production areas.

Easy Changeover

Quick adjustments under 5 minutes to accommodate different carton sizes.

Reliable Sealing

Ensures 100% secure sealing with hot melt glue or tape options.

VIDEOS

Drop Load Case Packer For Bottled drinks

Incredible Speed: Imagine packing 20 bottles into a case in just 3 seconds. With our Drop Load Case Packer, you can significantly ramp up your packaging speed to 20-30 cases per minute. Ideal for bottled drinks, it serves the beverage, food, cosmetics, and household products industries, ensuring efficient and reliable operation to meet your demanding production schedules.

Drop Load Case Packer For bagged food

Boost your efficiency with our Drop Load Case Packer for bagged food. Packing 10-25 cartons per minute, it’s perfect for the food industry, handling products like snacks, grains, and powders. This versatile machine ensures rapid, reliable packaging, meeting your high-demand production needs effortlessly.

Top Load Case Packer For bottled liquor

Enhance your production line with our Drop Load Case Packer for bottled liquor, packing 10-25 cartons per minute. Designed for the beverage industry, it handles various bottle sizes and shapes, ensuring consistent, high-volume packaging. Ideal for liquor, wine, and spirits, this machine guarantees efficient, reliable operation to meet your demanding production schedules.

LAYOUT DRAWINGS

Explore our extensive range of Packaging layout solutions tailored for your project needs.

RELATED EQUIPMENT

Integrated packaging line solutions

Horizontal Carton Erector Machine

The Horizontal Carton Erector Machine automates the opening, forming, and sealing of cartons, enhancing efficiency in packaging lines. Ideal for industries like food, pharmaceuticals, and electronics, it supports diverse carton sizes, ensuring consistent, precise assembly and sealing for streamlined production.

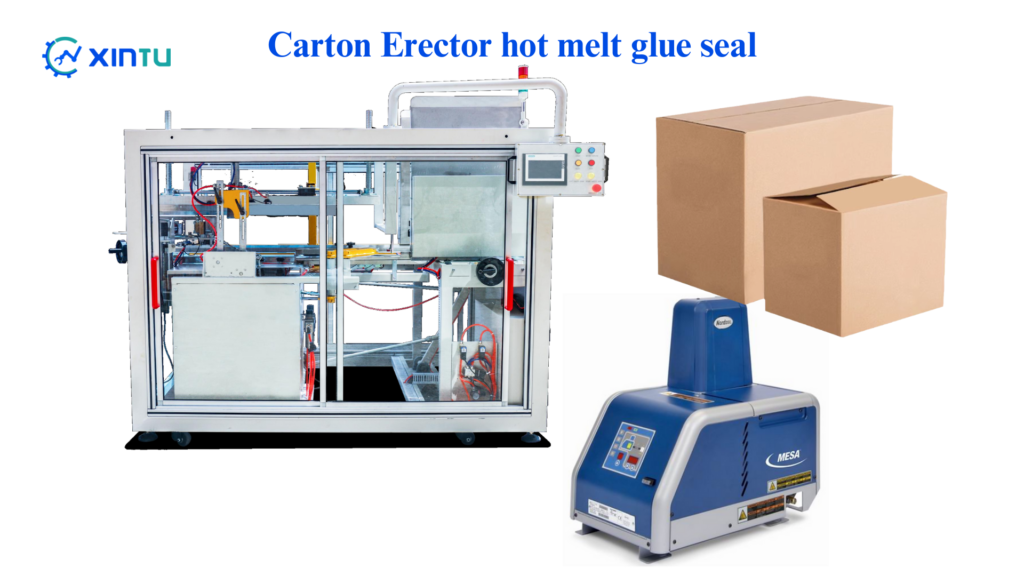

Hot Melt Glue Case Erector

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Automatic High Speed Case Erector Machine

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

FAQ

Listed below are the types of technical questions you may have about XINTU Automatic Carton Erector.

Working Principles of XINTU Case Erector Machine

The XINTU Case Erector Machine is an advanced solution designed to automate the process of forming and sealing cartons, enhancing efficiency and precision in packaging operations. Here’s a breakdown of the working principles:

1. Carton Loading and Feeding:

The XINTU Case Erector Machine begins with the loading of flat carton blanks into the ergonomic, easy-access magazine. This Box Erecting Machine ensures a seamless and consistent feed of cartons into the system, allowing for continuous operation without downtime. The magazine can hold up to 100 cartons, providing substantial input capacity.

2. Carton Forming:

Once the carton blanks are fed, the machine transitions to the forming stage, where each blank is opened and shaped into a box. The Automatic Carton Erector utilizes a sophisticated vacuum pick-and-place mechanism with eight suction cups that engage the leading and trailing panels of the carton. This precise method ensures that each carton is opened to a perfect 90-degree angle, maintaining its structural integrity.

3. Flap Folding and Bottom Sealing:

As the carton is erected, the bottom flaps are automatically folded and sealed. The Case Erector Machine offers both tape sealing and hot melt glue sealing options, allowing flexibility based on the packaging needs. The Carton Sealing Equipment ensures that each carton is sealed uniformly, providing a secure base for product filling. This machine can handle up to 20 cases per minute, making it a High-Speed Box Erector.

4. Carton Ejection and Transfer:

After sealing, the carton is ejected from the machine and transferred to the next stage of the packaging line. The Packaging Automation Systems integrated into the XINTU Case Erector ensure that each carton is correctly oriented and transferred smoothly, minimizing the risk of jams or disruptions in the production line.

5. Advanced Control Systems:

The machine features an intuitive PLC control system with a user-friendly interface. Operators can easily monitor and adjust settings, ensuring optimal performance and minimal downtime. The system includes automated alerts for any issues, ensuring quick response times.

Maintenance of Your XINTU Automatic Carton Erector

Regular maintenance of the XINTU Case Erector Machine is crucial to ensure its longevity and optimal performance. Proper maintenance not only helps in minimizing downtime but also maintains the precision and efficiency of your packaging operations. Here’s a comprehensive guide on how to maintain your Carton Forming and Bottom Sealing Machine effectively:

1. Routine Inspection and Cleaning:

- Daily Checks: Perform daily inspections to identify any visible signs of wear or damage. Focus on key components such as the suction cups, flaps, and sealing mechanisms of the Automatic Carton Erector.

- Cleaning: Regular cleaning is essential to prevent dust and debris buildup. Use compressed air to clean sensitive areas, and wipe down surfaces with a soft, damp cloth. Ensure that the Box Erecting Machine is free of any carton particles that may hinder performance.

- Lubrication: Apply lubricant to moving parts such as the gears, chains, and bearings. This ensures smooth operation and reduces friction, extending the life of your Case Erector Machine components.

2. Component Testing and Replacement:

- Sealing Equipment: Regularly test the performance of the Carton Sealing Equipment. For hot melt glue systems, ensure that the glue applicators are clean and functioning correctly. If you’re using tape, check the tape tension and alignment.

- Suction Mechanism: Inspect the vacuum suction system for leaks or damage. Replace worn-out suction cups to maintain the machine’s ability to properly erect and form boxes.

- Sensors and Electricals: Check all electrical connections and sensors to ensure they are operational. Faulty sensors can lead to misalignments and reduced efficiency in the High-Speed Box Erector.

3. Software and Control Systems:

- PLC System Updates: Keep the machine’s PLC and software systems updated to the latest version. This ensures improved functionality and security.

- User Interface Calibration: Regularly calibrate the user interface and control systems for precise operations. This includes adjusting settings for carton size and speed on your Carton Forming Equipment.

4. Scheduled Professional Servicing:

- Professional Maintenance: Schedule regular maintenance checks with XINTU’s professional service team. Our technicians are trained to provide comprehensive servicing, ensuring your Automatic Box Erector operates at peak performance.

- Replacement Parts: Use only genuine XINTU replacement parts for repairs. This maintains the machine’s integrity and performance standards.

Benefits of Regular Maintenance:

Regular maintenance of your Corrugated Box Erector results in reduced operational downtime, consistent performance, and prolonged equipment lifespan. Additionally, well-maintained machines contribute to better product quality and increased productivity in your packaging operations.

Investing time in routine maintenance checks ensures that your XINTU Case Erector Machine remains a reliable and efficient component of your Packaging Automation Systems. Proper care and servicing ultimately lead to smoother operations and a more streamlined packaging process.

For any maintenance assistance or to schedule a professional service, contact XINTU today. Our dedicated support team is here to help you keep your Case Erecting Machine running smoothly and efficiently.

The XINTU Case Erector Machine is engineered with advanced technology to provide efficient, reliable, and high-speed packaging solutions. Below, we outline the key technological features that make this machine a top choice in the industry:

1. Advanced Carton Forming and Bottom Sealing Technology:

- Precision Forming: The XINTU Carton Forming and Bottom Sealing Machine utilizes state-of-the-art mechanisms to ensure each box is perfectly formed and sealed. The precision-forming technology maintains structural integrity, producing consistent and square boxes for optimal stacking and transport.

- Dynamic Sealing Options: This Case Erector Machine offers both tape and hot melt glue sealing options. The Carton Sealing Equipment is designed to deliver uniform sealing, providing flexibility to adapt to various packaging needs.

2. Automated Control Systems:

- Intelligent PLC System: The machine is equipped with a sophisticated PLC (Programmable Logic Controller) that offers seamless control over operations. This automation allows for quick adjustments, ensuring efficient handling of different box sizes and materials in the Automatic Box Erector.

- Touchscreen Interface: The user-friendly touchscreen interface allows operators to easily navigate settings and monitor the status of the machine, enhancing productivity and reducing the potential for human error.

3. High-Speed Operation and Efficiency:

- Rapid Throughput: Designed as a High-Speed Box Erector, the XINTU Case Erector can process up to 30 cartons per minute, making it ideal for high-demand production environments.

- Energy Efficiency: The machine's advanced motor and energy management systems minimize power consumption while maintaining high output, making it an eco-friendly choice for Packaging Automation Systems.

4. Versatile and Adaptive Design:

- Adjustable Components: The Carton Forming Equipment features adjustable components that accommodate a wide range of carton sizes and styles. This adaptability ensures compatibility with various product lines and packaging requirements.

- Compact Footprint: With its compact and ergonomic design, the Corrugated Box Erector fits seamlessly into existing production lines, optimizing space and workflow.

5. Robust Construction and Durability:

- Sturdy Build: Engineered with a durable frame and high-quality materials, the XINTU Case Formers withstands rigorous production cycles, offering longevity and reliability in demanding industrial environments.

- Safety Features: Safety sensors and protective barriers are integrated into the design to safeguard operators and enhance operational safety during high-speed packaging.

Innovation and Reliability with XINTU:

The XINTU Case Erector Machine stands out with its innovative technology and reliability, making it an essential tool for modern packaging operations. Its cutting-edge features ensure that it not only meets but exceeds the expectations of businesses looking for efficiency, adaptability, and top-tier performance in their Carton Erectors.

With these advanced technological capabilities, the XINTU Case Erector Machine is a powerful asset that enhances productivity and streamlines operations, helping businesses meet their packaging goals with precision and ease. Whether you are in food, pharmaceuticals, electronics, or any industry requiring efficient packaging, XINTU provides the technology and support to optimize your production line.

For further information on how XINTU's technology can transform your packaging process, contact our team today. Experience the future of packaging automation with XINTU's innovative solutions.

How do I properly install the XINTU Case Erector Machine?

Installing the XINTU Case Erector Machine correctly is crucial for ensuring optimal performance and longevity.

1. Site Preparation

Choose the Right Location: Ensure that the installation site has a flat and stable floor surface that can support the machine's weight. Make sure there is adequate space for the machine's footprint and for operators to move around comfortably.

Power Supply Setup: The Automatic Carton Erector requires a stable power supply with the specifications provided in the machine's manual. Verify that the power supply meets the voltage and frequency requirements and that electrical outlets are within reach.

Air Supply Requirements: Connect the machine to a clean and dry air supply. The Box Erecting Machine typically needs an air pressure of 6-7kg/cm². Use high-quality air compressors to maintain consistent air pressure for reliable performance.

2. Machine Positioning and Alignment

Positioning the Machine: Carefully move the Case Erector Machine to its designated location using appropriate lifting equipment. Ensure the machine is level to prevent operational issues.

Alignment Checks: Use a spirit level to ensure that the machine is perfectly horizontal. Adjust the leveling feet as needed to maintain stability and prevent vibrations during operation.

3. Connecting Utilities

Electrical Connections: Follow the wiring diagram provided in the manual to connect the machine to the power supply. Ensure that all connections are secure and comply with local electrical regulations.

Air Line Installation: Connect the air lines from the compressor to the machine's air inlet. Double-check all connections to ensure there are no leaks that could compromise the operation of the Carton Sealing Equipment.

4. Assembly of Components

Installing Conveyor Belts: If your High-Speed Box Erector includes conveyor belts, follow the assembly instructions to install them properly. Ensure that belts are tensioned correctly to avoid slippage.

Attaching Safety Guards: Assemble and attach any safety guards or protective barriers as outlined in the installation guide. These features are critical for operator safety during the machine's operation.

5. Initial Calibration and Testing

Calibration Procedures: Once the machine is assembled, perform initial calibration according to the instructions. This step ensures that the Carton Forming Equipment operates within specified parameters and produces square cases without jamming.

Testing the Machine: Run a series of test cycles with sample cartons to verify that the Automatic Box Erector functions correctly. Check for proper case forming, sealing, and throughput.

6. Training and Safety Compliance

Operator Training: Ensure that all operators receive comprehensive training on how to operate the Corrugated Box Erector safely and efficiently. This training should cover routine maintenance procedures and troubleshooting common issues.

Safety Compliance: Confirm that the installation complies with all relevant safety standards and regulations. Regularly inspect the machine for wear and tear and ensure safety features are functioning correctly.

Follow these detailed steps to seamlessly set up your Carton Forming and Bottom Sealing Machine and maximize its efficiency:

Yes, the XINTU Case Erector Machine is designed with versatility in mind, making it capable of handling a wide variety of carton sizes and shapes. Our advanced Carton Forming and Bottom Sealing Machine offers flexible adjustments and features that cater to different packaging needs, making it an ideal choice for businesses across various industries. Here’s how our Automatic Carton Erector excels in managing diverse packaging requirements:

1. Wide Range of Carton Sizes

Adjustable Dimensions: The XINTU Box Erecting Machine can accommodate cartons with dimensions ranging from 250-450mm in length, 150-400mm in width, and 100-400mm in height. This flexibility allows you to switch seamlessly between different product lines without the need for extensive machine adjustments.

Customizable Configurations: Our Case Erector Machine offers customizable settings to handle specific carton sizes, making it easy to cater to unique packaging requirements and customer preferences.

2. Multi-Shape Carton Handling

Versatile Carton Shapes: Whether you need to package square, rectangular, or irregularly shaped cartons, the XINTU Carton Erector is equipped to handle various shapes with precision and ease.

Efficient Adaptability: The machine's adaptable design ensures consistent performance across a range of carton shapes, reducing downtime and enhancing productivity.

3. Advanced Automation for Easy Adjustments

Quick Changeover: The Automatic Box Erector features an intuitive adjustment system that allows for quick changeovers between different carton sizes and shapes. This minimizes setup time and maximizes operational efficiency.

User-Friendly Interface: The integrated PLC and HMI control system simplifies the process of adjusting settings for different carton configurations, ensuring smooth transitions and reliable operation.

4. Precision Engineering for Reliable Handling

Accurate Carton Forming: The XINTU High-Speed Box Erector employs precision engineering to ensure that each carton is formed accurately, maintaining structural integrity and preventing deformation.

Consistent Sealing: Our Carton Sealing Equipment provides consistent sealing quality, whether using tape or hot melt glue, guaranteeing secure and professional packaging for various carton sizes and shapes.

5. Ideal for Diverse Industries

Wide Applicability: The XINTU Corrugated Box Erector is suitable for a broad spectrum of industries, including food and beverage, pharmaceuticals, cosmetics, electronics, and more. Its ability to handle different carton sizes and shapes makes it an essential tool for companies with diverse product lines.

Scalable Solutions: As your business grows and your packaging needs evolve, the XINTU Packaging Automation Systems can scale to meet your demands, providing reliable support for expanding operations.

XINTU offers a diverse range of Case Erector Machines to suit various packaging needs. Our machines are designed to optimize efficiency, reduce labor costs, and provide reliable performance across different industries. Here are the main types of XINTU Case Erector Machines and their specific features:

1. Vertical Case Erector

Description: The Vertical Case Erector is designed for high-speed operations, forming and sealing cartons with precision. It utilizes gravity-assisted mechanisms for efficient carton handling.

Features:

- Speed: Capable of erecting up to 30 cartons per minute.

- Sealing Options: Compatible with both tape and hot melt glue sealing.

- Application: Ideal for industries requiring upright cartons, such as beverages and pharmaceuticals.

2. Horizontal Case Erector

Description: The Horizontal Case Erector is perfect for larger cartons or products that need to be loaded horizontally. It provides a seamless transition for products that are bulkier or longer.

Features:

- Speed: Handles up to 20 cartons per minute with precision alignment.

- Sealing Options: Offers tape and hot melt glue sealing options.

- Application: Suitable for electronics, home appliances, and larger consumer goods.

3. Servo Case Erector

Description: The Servo Case Erector employs servo-driven technology for enhanced precision and control. This machine ensures consistent carton forming and reduces mechanical wear.

Features:

- Speed: Can erect up to 40 cartons per minute, with minimal downtime.

- Technology: Servo motors provide smooth operation and precise control over carton dimensions.

- Application: Best for industries with high volume and precision needs, such as cosmetics and healthcare.

4. Robotic Case Erector

Description: The Robotic Case Erector integrates robotic arms for versatile handling of diverse carton shapes and sizes. It offers unmatched flexibility and automation.

Features:

- Speed: Operates efficiently with customizable speeds based on the complexity of tasks.

- Flexibility: Handles various carton types with ease, thanks to robotic adaptability.

- Application: Ideal for industries requiring high customization, such as automotive parts and specialized packaging.

5. Semi-Automatic Case Erector

Description: The Semi-Automatic Case Erector provides an economical solution for smaller operations, offering manual carton loading with automatic forming and sealing.

Features:

- Speed: Erects cartons at a moderate pace, suitable for small to medium-sized operations.

- Sealing Options: Equipped with tape sealing, with options for hot melt glue.

- Application: Perfect for startups or smaller enterprises in food and retail packaging.

XINTU Case Erector Machines offer a range of efficiency benefits designed to streamline your packaging processes and maximize productivity. Here are some key advantages:

1. Increased Production Speed

XINTU Case Erector Machines are designed to handle high-speed operations, with the ability to erect up to 40 cartons per minute. This rapid pace significantly boosts production capacity, allowing you to meet tight deadlines and high-demand periods effortlessly. By automating the carton erecting process, you eliminate the bottlenecks often caused by manual handling, leading to smoother and faster production lines.

2. Labor Cost Reduction

Automating the carton erecting process with XINTU machines reduces the need for manual labor, which can be both costly and prone to errors. By minimizing the reliance on human intervention, your business can save on labor costs and reduce the likelihood of mistakes, ensuring consistent quality and productivity. This efficiency allows your workforce to focus on other critical tasks, enhancing overall operational effectiveness.

3. Enhanced Precision and Consistency

XINTU Case Erector Machines are engineered for precision and consistency. Each machine is equipped with advanced sensors and servo-driven mechanisms that ensure every carton is erected with perfect squareness and alignment. This precision reduces material wastage and ensures that cartons are properly formed for seamless packing and stacking, enhancing the reliability of your packaging operations.

4. Versatility and Adaptability

XINTU machines are designed to handle a wide range of carton sizes and types, making them versatile tools for various industries. Whether you need to erect small, delicate cartons or larger, more robust cases, XINTU Case Erectors can be easily adjusted to meet your specific packaging needs. This adaptability allows you to switch between different products and packaging requirements without significant downtime, ensuring continuous productivity.

5. Improved Safety and Ergonomics

With features like automated feeding systems and intuitive controls, XINTU Case Erector Machines enhance workplace safety by minimizing the need for manual handling. This not only protects your workforce from potential injuries but also improves ergonomics by reducing the physical strain associated with manual carton erecting. The result is a safer, more comfortable working environment that contributes to higher employee satisfaction and retention.

6. Energy Efficiency

XINTU Case Erector Machines are designed with energy efficiency in mind, utilizing advanced technology to minimize power consumption without compromising performance. This not only reduces operational costs but also aligns with sustainability goals, helping your business reduce its environmental footprint while maintaining high levels of productivity.

7. Reliability and Low Maintenance

Built with durable materials and robust construction, XINTU Case Erector Machines are engineered for long-lasting performance with minimal maintenance requirements. This reliability ensures that your production line remains operational with minimal downtime, contributing to consistent productivity and efficiency. Regular maintenance is straightforward, reducing the time and resources needed for machine upkeep.

By integrating XINTU Case Erector Machines into your packaging operations, you can significantly enhance efficiency, reduce costs, and improve overall production quality. These machines are an investment in the future of your business, offering tangible benefits that support growth and competitiveness in the market.

XINTU Case Erector Machines are equipped with a wide array of advanced features designed to enhance efficiency, precision, and ease of use in your packaging operations. Here are the main features that make these machines stand out:

1. High-Speed Operation

XINTU Case Erector Machines are designed for rapid performance, capable of erecting up to 40 cartons per minute. This high-speed operation is ideal for businesses looking to maximize productivity and throughput in demanding environments. By minimizing cycle times, these machines help you maintain a smooth and efficient production line.

2. Advanced Control Systems

Each machine is equipped with state-of-the-art control systems, including PLC and HMI interfaces, allowing for easy operation and monitoring. The user-friendly touchscreens provide real-time data and diagnostics, making it simple to adjust settings and troubleshoot any issues that arise. This advanced technology ensures consistent performance and reliability.

3. Versatile Carton Handling

XINTU Case Erectors are capable of handling a variety of carton sizes and types, from small boxes to large cases. The machines can be easily adjusted to accommodate different dimensions, making them versatile tools suitable for multiple industries. Whether you need to package food, electronics, or pharmaceuticals, XINTU machines offer the flexibility to meet your specific needs.

4. Durable Construction

Built with high-quality materials and precision engineering, XINTU Case Erector Machines offer robust construction designed for long-lasting durability. The machines are crafted to withstand the rigors of continuous operation, ensuring reliable performance and minimizing the need for frequent maintenance or repairs.

5. Efficient Sealing Options

XINTU machines come with various sealing options, including hot melt glue and tape sealing, to suit different packaging requirements. The efficient sealing mechanisms ensure that each carton is securely closed, preventing damage or contamination during transport. This feature guarantees the integrity of your products, enhancing customer satisfaction.

6. Easy Integration

Designed with compatibility in mind, XINTU Case Erector Machines can be seamlessly integrated into existing production lines. The compact design and adjustable components allow for straightforward installation, whether you are implementing the machines in a new setup or retrofitting existing equipment. This adaptability ensures minimal disruption to your operations.

7. Safety Features

Safety is a top priority for XINTU, and the Case Erector Machines are equipped with multiple safety features, such as automatic stop functions and protective enclosures. These safety measures protect operators from potential hazards, creating a safer work environment and reducing the risk of workplace accidents.

8. Low Maintenance Requirements

XINTU Case Erector Machines are designed for minimal maintenance, with components that are easy to access and service. Regular maintenance is straightforward, helping you reduce downtime and keep your production line running smoothly. The machines' reliability ensures consistent performance over time.

Consistent packing is crucial for maintaining product quality, minimizing waste, and ensuring efficient logistics. XINTU Case Erector Machines are engineered to deliver reliable and uniform packing results through a combination of advanced technologies, precise engineering, and user-friendly features. Here’s how we ensure consistent packing with our machines:

1. Precision Engineering

XINTU Case Erector Machines are built with high-precision components that ensure accurate case forming and sealing. The machines utilize advanced sensors and control systems to monitor and adjust the packing process in real time, guaranteeing that each box is formed and sealed with perfect alignment and integrity. This precision minimizes errors and ensures that each carton meets the required specifications.

2. Intelligent Control Systems

Our machines feature sophisticated PLC and HMI control systems that allow operators to easily program and adjust settings for different carton sizes and types. The intelligent control systems ensure that each step of the packing process is executed with accuracy and consistency, reducing the risk of variability and improving overall packing quality. Operators can also monitor performance and make adjustments on the fly, ensuring optimal results.

3. Versatile Carton Handling

XINTU Case Erector Machines are designed to handle a wide variety of carton sizes and materials, making them adaptable to different packaging needs. The machines can quickly switch between different settings, allowing for seamless transitions between products without sacrificing consistency. This versatility ensures that all products, regardless of shape or size, are packed with the same level of precision and care.

4. Robust Construction

Durability is key to consistent performance, and XINTU machines are built to last. Constructed with high-quality materials and designed to withstand continuous operation, our case erectors deliver reliable packing results over extended periods. The robust design minimizes downtime and maintenance needs, keeping your production line running smoothly and consistently.

5. Advanced Sealing Technology

Our case erectors come equipped with advanced sealing options, including hot melt glue and tape sealing, to ensure secure and consistent carton closures. The sealing systems are finely tuned to apply the right amount of adhesive or tape, providing a uniform seal that protects the contents and maintains the integrity of the packaging. This technology reduces the risk of carton failure during shipping and handling.

6. Quality Assurance Measures

XINTU implements rigorous quality assurance measures to ensure that each case erector machine meets the highest standards of performance and reliability. Our machines undergo extensive testing and calibration to verify their ability to deliver consistent packing results. This commitment to quality ensures that our customers receive equipment that performs flawlessly, batch after batch.

7. Operator Training and Support

To maximize the potential of our machines, XINTU provides comprehensive training and support for operators. Proper training ensures that operators understand how to set up and operate the machines effectively, leading to consistent packing results. Our support team is always available to assist with any questions or technical issues, ensuring smooth and efficient operation.

By leveraging these features and strategies, XINTU Case Erector Machines provide consistent, reliable packing that supports your business's operational efficiency and product quality. Whether you’re handling small batches or high-volume production, our machines are designed to meet your needs with precision and consistency.

Integrating XINTU Case Erector Machines into your existing production line can significantly enhance efficiency, productivity, and consistency. Our machines are designed to seamlessly fit into various manufacturing and packaging environments, offering flexibility and ease of use. Here’s how you can integrate XINTU Case Erector Machines into your production line:

1. Compatibility Assessment

Before integration, it is essential to conduct a compatibility assessment to ensure that the XINTU Case Erector Machine aligns with your existing equipment and processes. Our experts can work with you to analyze your current setup, identifying areas where the case erector can be integrated most effectively. This assessment helps tailor the machine to your specific production needs and ensures seamless compatibility.

2. Modular Design

XINTU Case Erector Machines feature a modular design that allows for easy customization and integration into various production lines. Whether you have a small operation or a large-scale manufacturing facility, our machines can be configured to fit your space and align with your workflow. The modular components are easy to install and adapt, reducing the time and cost of integration.

3. Flexible Connectivity

Our case erectors are equipped with advanced connectivity options, making it simple to interface with other machines and systems in your production line. They support a range of communication protocols, ensuring compatibility with your existing automation systems. This connectivity enables real-time data exchange, coordination, and control, allowing for synchronized operation across the production line.

4. Automated Synchronization

XINTU machines are designed to integrate seamlessly with automated production lines, providing synchronized operations that enhance overall efficiency. They can be programmed to work in tandem with upstream and downstream equipment, ensuring smooth transitions and minimizing bottlenecks. This automated synchronization helps maintain a steady production flow, reducing downtime and increasing throughput.

5. Customization Options

We offer customization options to ensure that the XINTU Case Erector Machine meets your specific production requirements. Whether you need to handle different carton sizes, sealing methods, or production speeds, our team can tailor the machine’s features to align with your existing processes. This customization ensures optimal performance and seamless integration into your production line.

6. Easy Installation Process

The installation of XINTU Case Erector Machines is straightforward and efficient, thanks to our comprehensive installation support and user-friendly design. Our technicians can assist with the installation process, ensuring that the machine is correctly set up and configured for your production line. The intuitive design also makes it easy for your team to understand and operate the machine, facilitating a smooth transition.

7. Operator Training and Support

To maximize the benefits of integration, XINTU provides thorough training and support for your operators. Our training programs cover machine operation, maintenance, and troubleshooting, empowering your team to utilize the case erector effectively. Our support team is always available to assist with any questions or challenges, ensuring ongoing success and productivity.

8. Integration with Existing Software Systems

XINTU Case Erector Machines can be integrated with your existing software systems for enhanced control and monitoring. They are compatible with popular ERP and MES systems, allowing for real-time tracking, data collection, and analysis. This integration provides valuable insights into your production processes, enabling data-driven decision-making and continuous improvement.

9. Safety and Compliance

Safety is a top priority at XINTU, and our case erectors are built to meet the highest safety standards. When integrating our machines into your production line, you can be confident that they will comply with all relevant regulations and safety protocols. Our team can also help you assess your production line for safety improvements, ensuring a safe and efficient working environment.

By focusing on these integration strategies, XINTU Case Erector Machines can become a vital part of your production line, enhancing efficiency and ensuring consistent, high-quality results. Whether you’re expanding your operations or upgrading your existing equipment, XINTU is here to support your success with innovative and reliable packaging solutions.

At XINTU, we offer a diverse range of Case Erector Machines, each designed to meet specific production needs and capacities. Our machines are engineered for efficiency and precision, catering to various industries and packaging requirements. Here’s an overview of the production capacity of different models of XINTU Case Erector Machines:

1. XINTU-CPC01 Vertical Case Erector

- Production Capacity: 12 cases per minute

- Features: Ideal for medium-volume operations, this model is perfect for industries requiring consistent and reliable case erecting. It’s equipped with advanced Carton Forming and Bottom Sealing Machine technology, making it suitable for packaging products in the food, beverage, and pharmaceutical sectors.

- Applications: Suitable for packaging consumer goods, electronics, and personal care products, where moderate speed and precision are essential.

2. XINTU-MCEV01 High-Speed Horizontal Case Erector

- Production Capacity: 20 to 40 cases per minute

- Features: This high-speed Box Erector is designed for large-scale operations where efficiency and speed are critical. It features automatic carton erecting with hot melt glue sealing, making it ideal for industries with high demand and fast-paced environments.

- Applications: Perfect for the beverage, dairy, and food processing industries, where high-speed packaging is necessary to maintain production flow.

3. XINTU-SCE01 Servo Case Erector

- Production Capacity: 5 to 30 cases per minute

- Features: The Servo Carton Erector model offers precision and adaptability with servo motor technology, allowing for quick changeovers and adjustments. It’s a versatile solution for companies needing to package a variety of product sizes with efficiency.

- Applications: Best suited for pharmaceuticals, electronics, and industrial goods, where flexibility in carton size and rapid changeovers are needed.

4. XINTU-RCE01 Robotic Case Erector

- Production Capacity: 10 to 25 cases per minute

- Features: The Robotic Case Erector is designed for automation and precision, utilizing robotics to handle complex packaging tasks. It integrates seamlessly into automated production lines, enhancing productivity and reducing labor costs.

- Applications: Ideal for e-commerce, logistics, and manufacturing sectors where automation and precision are paramount.

5. XINTU-SACE01 Semi-Automatic Case Erector

- Production Capacity: 8 to 15 cases per minute

- Features: This Semi-Automatic Case Erector offers a cost-effective solution for small to medium-sized businesses looking to improve packaging efficiency without fully automating the process. It provides manual input with automatic sealing capabilities.

- Applications: Suitable for small businesses, startups, and companies transitioning to automation, providing flexibility and ease of use.

6. XINTU-HGCE01 Corrugated Box Erector with Hot Melt Glue

- Production Capacity: 15 to 35 cases per minute

- Features: Designed for corrugated packaging, this model uses hot melt glue for sealing, ensuring robust and durable packaging solutions. It’s perfect for handling heavy-duty packaging needs with precision.

- Applications: Used in heavy industries, including automotive parts, hardware, and construction materials, where strong packaging is required.

Conclusion

XINTU Case Erector Machines are engineered to meet a variety of production needs, from small businesses to large industrial operations. Our diverse range of models ensures that we have the right solution for your specific packaging requirements, offering flexibility, efficiency, and precision. Whether you need a High-Speed Case Erector or a versatile Robotic Case Erector, XINTU has the perfect model to enhance your production line and improve your packaging operations. With advanced Packaging Automation Systems and state-of-the-art Carton Sealing Equipment, our machines provide a seamless integration into your existing setup, boosting productivity and ensuring consistent results.

Optimizing the efficiency of your XINTU Case Erector Machine involves several strategic actions to ensure maximum productivity, minimal downtime, and consistent performance. Here are key steps and practices to achieve optimal efficiency:

1. Regular Maintenance

Consistent upkeep: Regular maintenance checks are crucial for ensuring the smooth operation of your Case Erector Machine. Scheduled maintenance should include inspecting moving parts, lubrication, and replacing any worn-out components. By addressing minor issues early, you can prevent major breakdowns and prolong the machine’s lifespan.

Maintenance tips: Follow a comprehensive maintenance schedule that includes daily, weekly, and monthly tasks. Daily checks might include cleaning sensors and checking for debris, while weekly inspections could involve tightening belts and checking pneumatic systems. Monthly tasks should focus on in-depth inspections of all mechanical parts.

2. Proper Training for Operators

Skilled workforce: Training your operators to use the XINTU Case Erector efficiently is essential. A well-trained operator can quickly identify and resolve issues, reducing downtime and maintaining high efficiency.

Training programs: Implement comprehensive training programs that cover machine operations, troubleshooting common issues, and understanding the interface of the Carton Forming and Bottom Sealing Machine. Refresher courses can keep operators updated on the latest techniques and machine features.

3. Utilize the Correct Settings

Optimal settings: Using the correct machine settings for different carton sizes and types is vital. Ensure that the machine is configured correctly to handle specific packaging requirements, which will minimize jams and enhance throughput.

Adjustable features: The XINTU Case Erector Machine is designed with adjustable settings for carton dimensions, ensuring versatility and precision. Utilize these features to adapt to different packaging needs seamlessly, enhancing productivity and efficiency.

4. Monitor and Adjust Carton Supply

Consistent supply: A consistent supply of cartons is essential to keep the machine running smoothly. Ensure that the carton magazine is replenished regularly and that the cartons are aligned correctly to avoid interruptions.

Monitoring systems: Implement a monitoring system that tracks the supply of cartons and alerts operators when levels are low. This proactive approach reduces downtime and keeps the production line moving efficiently.

5. Integration with Other Systems

Seamless integration: Ensure your Case Erector Machine is integrated with other packaging automation systems for streamlined operations. This integration helps reduce bottlenecks and enhances the overall efficiency of your production line.

System synchronization: Use synchronization techniques to ensure that all parts of the production line, from Carton Forming Equipment to case sealing, are working together smoothly. This coordination minimizes delays and maximizes output.

6. Use High-Quality Materials

Material quality: Using high-quality cartons and adhesives can prevent machine malfunctions and improve the end product. Invest in robust materials that can withstand the packaging process and maintain structural integrity.

Vendor selection: Select reliable vendors for your packaging materials to ensure consistent quality. High-quality materials reduce the likelihood of jams and improve the efficiency of the XINTU Automatic Box Erector.

7. Leverage Technology and Automation

Technological advancements: Leverage the latest technology and automation features in the XINTU Case Erector Machine. Advanced technologies, such as automatic adjustments and real-time monitoring, can significantly boost efficiency.

Automation benefits: Fully utilize the automation capabilities of your machine, such as the High-Speed Box Erector and Carton Sealing Equipment, to reduce manual interventions and speed up the packaging process.

Conclusion

Optimizing the efficiency of your XINTU Case Erector Machine is a multifaceted approach that involves regular maintenance, proper operator training, and utilizing the machine’s advanced features. By following these steps, you can ensure that your Case Erector Machine operates at peak performance, enhancing your production line’s efficiency and delivering consistent, high-quality results. Investing in high-quality materials, integrating with other systems, and leveraging automation technologies will further solidify your packaging operations' effectiveness, making your processes more streamlined and productive.

The XINTU Vertical Case Erector Machine is designed for high efficiency and reliability, but like any complex machinery, it may occasionally encounter issues. Understanding these common problems and how to troubleshoot them effectively can help maintain seamless operations. Here are some typical issues and their solutions:

1. Case Jamming

Issue: One of the most frequent problems is case jamming during the forming or sealing process. This can be caused by misaligned cartons, irregular carton sizes, or debris in the machine.

Troubleshooting:

- Alignment checks: Regularly check the alignment of the carton feed system. Misalignment can cause cases to enter the machine at an angle, leading to jams.

- Size verification: Ensure that all cartons are within the specified size range for the machine. Out-of-specification cartons can disrupt the process.

- Debris removal: Regularly clean the machine to remove any debris that might interfere with the operation. A clean machine is less likely to experience jams.

2. Inconsistent Case Forming

Issue: Sometimes, the case former might not create properly squared boxes, affecting the stability of packed products.

Troubleshooting:

- Component inspection: Inspect the suction cups and pick arms for wear and tear. Damaged components may not handle cartons effectively.

- Suction pressure: Verify that the suction pressure is set correctly. Low pressure can prevent the machine from forming cases properly.

- Regular calibration: Schedule regular calibration sessions for the case former to ensure all mechanical parts are in sync and functioning as intended.

3. Adhesive Issues

Issue: The Case Erector Machine may experience problems with adhesive application, such as uneven gluing or failure to seal properly.

Troubleshooting:

- Glue inspection: Check the glue tank for the correct adhesive type and consistency. The wrong adhesive or improper viscosity can lead to application issues.

- Nozzle cleaning: Clean the adhesive nozzles regularly to prevent clogs that can disrupt even glue distribution.

- Temperature settings: Ensure that the hot melt adhesive system is operating at the correct temperature for optimal performance.

4. Carton Feed Problems

Issue: Cartons not feeding correctly into the machine can result in slowdowns or stoppages.

Troubleshooting:

- Feed alignment: Align the carton feed system properly to ensure smooth entry into the erector. Misalignment can cause cartons to catch or slip.

- Carton quality: Use high-quality, uniform cartons that meet the machine’s specifications. Variations in carton thickness or size can lead to feed problems.

- Feed rollers: Inspect and clean the feed rollers to ensure they are gripping and moving cartons as designed.

5. Electrical or Sensor Malfunctions

Issue: Electrical issues or faulty sensors can halt operations or produce erroneous readings.

Troubleshooting:

- Sensor checks: Regularly test all sensors to ensure they are functioning correctly. Clean sensor lenses to prevent dust or debris from causing false readings.

- Electrical inspection: Inspect all electrical connections and components for signs of wear, corrosion, or damage. Ensure that wiring is secure and components are properly connected.

- Professional servicing: Engage a qualified technician to perform regular electrical checks and maintenance, ensuring all systems are up to standard.

Conclusion

To maintain optimal performance and efficiency with your XINTU Vertical Case Erector Machine, it's important to proactively address common issues. By understanding these problems and implementing routine maintenance checks, your packaging line can operate with minimal interruptions. Regular inspections, cleaning, and professional servicing are key to preventing issues and extending the machine’s life. This proactive approach not only enhances productivity but also ensures the consistent quality of your packaging operations.

The energy requirements for the XINTU Vertical Case Erector Machine are designed to optimize efficiency while minimizing operational costs. Understanding these requirements can help you ensure proper installation and operation of your machine. Here are the key energy considerations for operating the XINTU Vertical Case Erector Machine:

1. Electrical Supply

- Voltage: The XINTU Vertical Case Erector Machine typically operates on a 220V or 380V electrical supply, depending on the specific model and regional requirements. It's important to verify the correct voltage to avoid damage to the machine.

- Phase: This machine can operate on a single-phase or three-phase power supply. A three-phase supply is generally preferred for industrial settings due to its stability and efficiency in powering larger equipment.

- Frequency: The standard frequency is 50Hz or 60Hz, which should match the local power grid specifications. Ensuring compatibility with local power standards is crucial for optimal performance.

2. Power Consumption

- Average Power Usage: The XINTU Vertical Case Erector Machine consumes approximately 1.5 to 2.5 kW, depending on the specific operations and configurations.

- Energy Efficiency: With its energy-efficient design, the machine minimizes power usage while maintaining high-speed operations, reducing overall energy costs. It utilizes advanced technology to achieve a balance between power and performance, making it a cost-effective choice for your packaging needs.

3. Compressed Air Requirements

- Pressure: The machine requires compressed air at a pressure of approximately 6-8 bar (87-116 psi) to operate pneumatic components, such as suction cups and actuators. Consistent pressure is essential for smooth operation and precise case erecting.

- Air Consumption: Typical air consumption is around 450-600 NL/min. It's important to have a reliable air compressor system that can supply the necessary air volume to maintain continuous operation without interruptions.

4. Environmental Considerations

- Temperature: The machine is designed to operate within a standard ambient temperature range of 0°C to 40°C (32°F to 104°F). Maintaining this temperature range helps ensure optimal machine performance and longevity.

- Humidity: Relative humidity levels should be kept below 90% non-condensing. Excessive moisture can affect electrical components and pneumatic systems, leading to potential malfunctions.

5. Operational Considerations

- Start-Up Power: The initial start-up may require a slightly higher power draw as the machine gears up to full operational speed. It's recommended to account for this when designing your electrical setup.

- Energy-Saving Features: The XINTU Vertical Case Erector Machine is equipped with energy-saving features, such as automatic standby modes and efficient motor designs, which help reduce power consumption during idle times.

Conclusion

Understanding the energy requirements of the XINTU Vertical Case Erector Machine allows for efficient setup and operation, ensuring your packaging line runs smoothly and cost-effectively. Proper installation and adherence to these specifications will not only enhance performance but also contribute to energy conservation and sustainability in your facility. This approach optimizes your packaging processes while minimizing environmental impact.

Ensuring the safety of operators and maintaining a safe work environment are top priorities when designing and operating any industrial machinery. The XINTU Vertical Case Erector incorporates a range of safety features to protect workers and enhance operational safety. Here’s a detailed look at the key safety features included in the XINTU Vertical Case Erector:

1. Emergency Stop Buttons

- Strategic Placement: Emergency stop buttons are strategically placed around the machine to provide easy access in case of an emergency. This allows operators to quickly halt operations to prevent accidents or equipment damage.

- Immediate Response: Activating an emergency stop button immediately cuts power to the machine, ensuring an instant stop of all mechanical and pneumatic functions. This feature is essential for mitigating potential hazards.

2. Safety Guarding and Interlocks

- Transparent Guarding: The machine is equipped with transparent safety guards that provide visibility while preventing access to moving parts. This design keeps operators safe from moving components without sacrificing visibility and monitoring.

- Interlock Systems: Safety interlocks ensure that the machine cannot operate unless all guards are securely in place. Opening a guard automatically stops the machine, preventing accidental operation during maintenance or adjustments.

3. Automatic Shutdown Sensors

- Jam Detection: Sensors detect any jams or blockages in the machine and trigger an automatic shutdown to prevent damage or injury. This feature minimizes downtime and reduces the risk of mechanical failures.

- Overload Protection: Built-in overload protection prevents the machine from operating beyond its capacity, reducing the risk of overheating and mechanical stress.

4. Warning Signals and Indicators

- Visual Alerts: The machine is equipped with visual indicators, such as flashing lights or LED displays, to alert operators of the machine’s status or any issues that require attention.

- Audible Alarms: Audible alarms provide additional warnings for critical situations, ensuring that operators are promptly notified of any safety concerns.

5. Controlled Access Points

- Restricted Access Panels: Access panels are designed to restrict entry to critical areas of the machine, reducing the likelihood of unauthorized tampering or accidental contact with sensitive components.

- Secure Locking Mechanisms: Panels and doors are equipped with secure locking mechanisms to prevent unintended access, ensuring that only authorized personnel can perform maintenance or adjustments.

6. Operator Training and Manuals

- Comprehensive Training: The XINTU Vertical Case Erector comes with detailed training programs and manuals to ensure that operators are fully educated on safe machine operation and maintenance.

- User-Friendly Interface: The machine’s user interface is designed for ease of use, minimizing the risk of operator error and enhancing safety through intuitive controls and clear instructions.

7. Environmental Safeguards

- Dust and Debris Protection: The machine’s design includes features to protect against dust and debris accumulation, reducing the risk of fires or mechanical issues caused by contaminants.

- Temperature Monitoring: Built-in temperature sensors monitor the machine’s environment, ensuring it operates within safe temperature ranges to prevent overheating.

Conclusion

The XINTU Vertical Case Erector is engineered with a comprehensive array of safety features to protect operators and maintain a secure work environment. From emergency stops and safety guards to advanced sensors and user-friendly interfaces, these features work together to ensure safe and efficient operations, helping you maintain a safe, productive, and compliant packaging line. Proper use of these safety features, along with regular training and maintenance, will maximize the safety and efficiency of your operations.

Selecting the right vertical case erector machine for your production line is crucial for optimizing efficiency, minimizing downtime, and ensuring that your packaging operations meet your business needs. Here are some key considerations to help you choose the most suitable vertical case erector machine for your operation:

1. Evaluate Your Production Requirements

Production Volume: Assess your current and projected production volumes to determine the necessary speed and capacity. If your production demands are high, consider a high-speed case erector that can handle a large number of cases per minute.

Box Dimensions: Consider the range of box sizes your operation will handle. Ensure the machine you choose can accommodate these dimensions and has the flexibility to adjust for different sizes if your needs change.

2. Consider Box Material and Design

Material Type: Consider the type of corrugated material or carton design you use. Some case erectors are better suited for thicker, double-wall cartons, while others work more efficiently with single-wall or specific box styles.

Flap and Seal Design: Ensure the machine supports your sealing method, whether it’s tape, hot melt glue, or self-locking bottoms. Each sealing type has distinct benefits and applications depending on the product weight, shipping conditions, and budget.

3. Determine Automation Level

Automation Needs: Decide between semi-automatic and fully automatic options. Fully automatic machines reduce labor costs and human intervention, ideal for high-volume operations. Semi-automatic models offer manual adjustments, which can be advantageous for smaller operations with varied packaging needs.

Integration with Existing Systems: Consider how the case erector will integrate with your existing packaging line. Look for machines that offer seamless connectivity with other equipment, such as conveyors, case packers, or palletizers, to create a cohesive system.

4. Assess Reliability and Maintenance

Machine Reliability: Research the machine's reliability and track record. Look for customer reviews or case studies that highlight the machine’s performance in real-world settings.

Maintenance Requirements: Evaluate the machine’s maintenance needs. Choose a model with minimal maintenance requirements and easy access to components for cleaning and repairs. Reliable technical support from the manufacturer is also a critical factor.

5. Budget Considerations

Initial Investment: Compare the initial costs of various models and balance this with your budget constraints. Remember that a higher upfront cost may be justified by long-term savings in efficiency and reduced labor.

Operational Costs: Factor in the long-term operational costs, such as energy consumption and maintenance expenses, to determine the machine’s total cost of ownership.

6. Supplier Support and Warranty

Technical Support: Ensure that the supplier offers robust technical support, including training, troubleshooting, and spare parts availability.

Warranty Coverage: Look for comprehensive warranty coverage to protect your investment and provide peace of mind in case of equipment failures.

Conclusion

Choosing the right vertical case erector machine requires careful consideration of your production needs, budget, and operational goals. By evaluating your requirements against the capabilities of different machines, you can select a vertical case erector that enhances your packaging efficiency and aligns with your business strategy. With the right choice, you can streamline your operations, reduce costs, and improve overall productivity.

Training your staff to operate a Vertical Case Erector safely is essential to maintain workplace safety, ensure efficient operation, and minimize the risk of accidents. Here are the key steps and considerations for a comprehensive training program:

1. Understand Machine Specifications and Manuals

Review Documentation: Begin with a thorough review of the machine’s operating manuals and specifications. Ensure that all operators are familiar with the manufacturer's guidelines, safety protocols, and machine capabilities.

Key Components Identification: Educate your staff on identifying and understanding the critical components of the Vertical Case Erector, including the control panel, sensors, emergency stop buttons, and moving parts.

2. Provide Hands-On Training

Demonstration Sessions: Conduct hands-on training sessions where experienced operators demonstrate the correct operation of the case erector. These sessions should cover all aspects of machine operation, including start-up procedures, adjustments, and shutdown processes.

Supervised Practice: Allow new operators to practice under supervision. This practical experience is crucial for building confidence and ensuring they can operate the machine independently.

3. Focus on Safety Protocols

Safety Equipment: Train operators on the importance of using personal protective equipment (PPE) such as gloves, safety goggles, and hearing protection when operating the machine.

Emergency Procedures: Educate staff on emergency shutdown procedures, the location of emergency stop buttons, and how to respond to machine malfunctions or safety incidents.

Hazard Awareness: Make operators aware of potential hazards, such as pinch points and moving parts, and instruct them on how to avoid accidents by maintaining a safe distance and keeping hands and clothing clear of the machine.

4. Routine Maintenance and Troubleshooting

Maintenance Training: Train staff on routine maintenance tasks such as cleaning, lubricating, and inspecting the machine for wear and tear. This training helps prevent breakdowns and ensures the machine operates efficiently.

Troubleshooting Skills: Equip operators with basic troubleshooting skills to identify and resolve minor issues that may arise during operation. Understanding common problems and their solutions can minimize downtime and maintain productivity.

5. Regular Updates and Refresher Courses

Ongoing Education: Implement regular refresher courses to keep operators updated on new features, safety protocols, and best practices. This continuous learning approach ensures that skills remain sharp and knowledge is current.

Feedback and Assessment: Encourage operators to provide feedback on their training experience and assess their performance regularly to identify areas for improvement.

6. Create a Safety-First Culture

Safety Meetings: Conduct regular safety meetings to discuss any incidents, share best practices, and reinforce the importance of safety in the workplace.

Incentives for Safe Practices: Consider implementing an incentive program to reward staff for adhering to safety protocols and maintaining a clean safety record.

Conclusion

Training staff to operate a Vertical Case Erector safely requires a structured approach that combines hands-on experience, safety education, and ongoing learning. By investing in comprehensive training, you ensure that your operators can use the equipment confidently and safely, ultimately leading to improved efficiency, reduced accidents, and a safer work environment.

The field of packaging automation has seen significant advancements, and Vertical Case Erectors are no exception. Here are the latest technological advancements in Vertical Case Erectors that enhance their performance, efficiency, and adaptability in modern production environments:

1. Advanced Automation and Control Systems

Smart Sensors: Modern Vertical Case Erectors are equipped with smart sensors that provide real-time data on machine performance, enabling predictive maintenance and reducing downtime. These sensors can detect anomalies and trigger alerts for operators to take action before problems escalate.

AI-Driven Controls: Artificial intelligence (AI) is being integrated into control systems, allowing machines to adapt to varying box sizes and shapes automatically. AI algorithms optimize the speed and accuracy of operations, leading to improved productivity.

2. Enhanced Flexibility and Customization

Adjustable Tooling: Vertical Case Erectors now feature adjustable tooling that accommodates a wide range of carton sizes and styles without the need for extensive manual adjustments. This flexibility is crucial for businesses handling diverse packaging requirements.

Modular Design: The modular design of new models allows for easy customization and integration with existing production lines. This adaptability means businesses can expand or modify their packaging processes without significant downtime or additional equipment.

3. Improved Safety Features

Safety Enclosures: Advanced safety enclosures and interlocks ensure that the machine stops automatically if a door or guard is opened, protecting operators from injury.

Enhanced Ergonomics: Ergonomically designed control panels and user interfaces make it easier for operators to interact with the machine, reducing fatigue and minimizing the risk of accidents.

4. Energy Efficiency

Eco-Friendly Operations: Newer models are designed with energy efficiency in mind, utilizing eco-friendly components and systems that reduce power consumption and lower operational costs.

Variable Frequency Drives (VFDs): VFDs allow precise control of motor speeds, optimizing energy use based on the workload. This technology not only saves energy but also extends the life of the machine by reducing mechanical stress.

5. Integration with IoT and Industry 4.0

IoT Connectivity: Vertical Case Erectors are now being integrated with Internet of Things (IoT) technology, enabling remote monitoring and control. This connectivity allows for seamless integration with larger production management systems and facilitates data-driven decision-making.

Industry 4.0 Compatibility: These machines are designed to fit into smart factory environments, where data is shared across various production units to optimize efficiency and throughput. This integration ensures that Vertical Case Erectors contribute to a cohesive and efficient production ecosystem.

6. High-Speed and Precision Performance

Faster Throughput: Advanced drive systems and precision components enable high-speed operations without sacrificing accuracy, allowing manufacturers to meet high demand with consistent quality.

Accurate Case Forming: Improved mechanical designs and technologies ensure perfect 90-degree angles and reliable sealing, enhancing the stability and appearance of packed cartons.

Conclusion

The latest technological advancements in Vertical Case Erectors make them indispensable tools in modern packaging operations. By incorporating cutting-edge automation, enhanced flexibility, improved safety, energy efficiency, and IoT integration, these machines are more capable than ever of meeting the evolving needs of various industries. Investing in advanced Vertical Case Erectors ensures that businesses can stay competitive, reduce operational costs, and achieve higher productivity in today's fast-paced market.