The XINTU Side Load Case Packer is designed for efficient and versatile packing solutions. This machine automatically arranges and layers products according to your specific packing requirements, ensuring smooth and hassle-free operation. With a broad range of applications, the Side Load Case Packer handles various product sizes and shapes. The integration of product sorting and packing in one station reduces the machine’s footprint, addressing space constraints commonly associated with traditional packers.

The system features a user-friendly PLC and touchscreen control panel, enabling easy fault detection and troubleshooting. Ideal for industries such as pharmaceuticals, food, cosmetics, and other light industries, this high-speed Side Load Packing Equipment guarantees reliable performance and increased productivity.

Main Features

Automated Sorting

Automatically arranges products for seamless packing.

Wide Application

Suitable for various product sizes and shapes.

Compact Design

Integrates sorting and packing to save space.

User-Friendly Control

PLC and touchscreen for easy operation and troubleshooting.

High Speed

Packs 200-360 boxes per hour efficiently.

Versatile Use

Ideal for pharmaceuticals, food, and light industries.

ADVANTAGES

High Efficiency

Packs up to 360 boxes/hour.

Space Saving

Compact design reduces footprint by 30%.

Versatile Application

Handles a wide range of carton sizes, 50-120mm.(Can be customized)

User-Friendly Operation

Easy troubleshooting with touchscreen interface.

SPECIFICATION

Speed

Up to 6 cases per minute

Up to 360 cases per hour

Packaging speed vary according to products quantity in a case.

Case sizes

L250-550*W250-400*H150-300mm

Available to customize

Operation

Side Push

Changeover

- Quick Release Mechanism: Switch between product types in less than 3 minutes.

- Preset Configurations: Save up to 10 presets for fast changeovers within 2 minutes.

- Tool-Free Adjustments: Adjust for different carton sizes in under 5 minutes.

Construction

Carbon Steel Frame

Ensures strong and durable support structure for the machine.

Stainless Steel Contact Parts

Provides corrosion resistance and hygiene for all product contact areas.

Control Method

PLC + touch screen + standard control buttons + signal switch, automatic / manual control modes optional

Power Supply

380V/50Hz or 60Hz(Customized to the industrial voltage of the customer’s plant)

Air Supply

0.5-0.7Mpa,Approx. 5-6kg/㎠ 460L/min

Package Support

Cigarette boxes, Medicine boxes, Cosmetic boxes, Boxed food, Canned beverages, Canned food, and Bottled beverages.

Case Support

RSC cartons or cartons with side openings

VIDEOS

Side Load Case Packer for bagged snacks

The XINTU Side Load Case Packer is an ideal solution for the bagged snacks industry, offering high-speed, efficient, and reliable packing. This Side Load Case Packer can handle speeds up to 360 cases per hour, ensuring that your production line maintains optimal throughput. Suitable for various products such as chips, pretzels, and other bagged snacks, this machine seamlessly integrates into existing end-of-line packaging systems. The Side Load Packaging Machine is designed to handle a wide range of case sizes, making it versatile for different packaging requirements in the food and snack industry. With the Side Load Case Packing System, you achieve consistent, precise packing, reducing manual labor and increasing productivity. Choose XINTU’s End-of-Line Side Load Packer to enhance your packing efficiency and meet industry demands.

Side Load Case Packer for bottled drinks

The XINTU Side Load Case Packer for bottled drinks is engineered for high efficiency and reliability. This machine can pack up to 360 cases per hour, ensuring your production line keeps pace with industry demands. Ideal for the beverage industry, the Side Load Case Packer handles various bottled drinks, including water, juices, and soft drinks. Its advanced technology and design allow it to seamlessly integrate into your end-of-line packaging system, optimizing throughput and minimizing downtime. The Side Load Packaging Machine is perfect for maintaining product integrity and packaging consistency. With features like the Automatic Side Load Packer and the Side Load Carton Packer, you can trust XINTU’s Side Load Packing Equipment to boost your production efficiency and meet market needs.

Top Load Case Packer For bottled liquor

Enhance your production line with our Drop Load Case Packer for bottled liquor, packing 10-25 cartons per minute. Designed for the beverage industry, it handles various bottle sizes and shapes, ensuring consistent, high-volume packaging. Ideal for liquor, wine, and spirits, this machine guarantees efficient, reliable operation to meet your demanding production schedules.

LAYOUT DRAWINGS

Explore our extensive range of Packaging layout solutions tailored for your project needs.

Layout of Side Load Case Packer

360 cases per hour case packing machine layout for food&beverage plants,Daily chemicals factory,Pharmaceutical plants.

RELATED EQUIPMENT

Integrated packaging line solutions

Add Your Heading Text Here

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Add Your Heading Text Here

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Add Your Heading Text Here

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

FAQ

Listed below are the types of technical questions you may have about XINTU Side Load Case Packing Machine

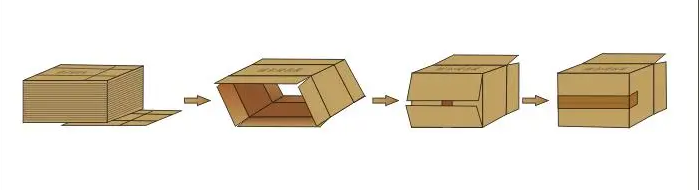

Working Principles of XINTU Side Load Case Packer

The XINTU Side Load Case Packer operates with precision and efficiency to streamline your packaging process. This Side Loading Case Packer is designed to automatically handle products, guiding them into cases from the side. The Side Load Packaging Machine features an advanced system that opens and positions the carton, ensuring seamless product entry and alignment.

As an Automatic Side Load Packer, it is equipped with sensors and PLC controls that facilitate smooth operation and prevent jams. The Side Entry Case Packer is highly versatile, capable of accommodating various carton sizes and configurations. Its robust design allows it to integrate seamlessly with your existing Side Load Packing Equipment, forming a comprehensive Side Load Case Packing System.

Engineered for high-speed operations, this High-Speed Side Load Packer enhances productivity while maintaining consistency and accuracy. The End-of-Line Side Load Packer is ideal for industries that require reliable and efficient secondary packaging solutions, ensuring that products are packed securely and ready for distribution.

Key components like the Side Load Carton Packer and the Side Load Packing Equipment ensure the machine delivers optimal performance, making it a crucial part of any automated packaging line.

Maintenance of Your XINTU Side Load Case Packer

How often should I perform maintenance on my Side Load Case Packer?

Regular maintenance should be performed on your Side Load Case Packer every 6 months to ensure optimal performance and longevity. More frequent checks might be necessary depending on the usage and workload of your machine.

What components require the most attention during maintenance?

Key components of the Side Loading Case Packer that require regular inspection and cleaning include moving parts, sensors, and the PLC control system. Ensure that the Side Load Packaging Machine’s moving parts are free from debris and properly lubricated.

How do I maintain the Automatic Side Load Packer’s sensors and PLC controls?

Regularly check and calibrate the sensors and PLC controls of your Automatic Side Load Packer to maintain precise operation. Perform diagnostic checks and software updates as part of your routine maintenance to ensure accurate performance.

What should I do to prevent downtime in my Side Entry Case Packer?

Preventing downtime in your Side Entry Case Packer involves routine inspections and immediate replacement of any worn or damaged parts. Ensure the carton positioning and product alignment mechanisms are always accurate by performing regular adjustments.

How do I maintain the lubrication of my Side Load Carton Packer?

Maintain the Side Load Carton Packer by regularly lubricating all mechanical parts to minimize friction and wear. Use the manufacturer-recommended lubricants and follow the lubrication schedule outlined in the user manual.

How can I ensure my Side Load Packing Equipment operates at high speed?

To ensure your High-Speed Side Load Packer operates at optimal speed, monitor and maintain the speed settings. Avoid overloading the packing system to prevent mechanical stress and ensure smooth operation.

What should be included in the maintenance plan for the Side Load Case Packing System?

A comprehensive maintenance plan for the Side Load Case Packing System should include regular inspections, lubrication, calibration of sensors, replacement of worn parts, and software updates. Integrate these tasks into a routine schedule to avoid unexpected downtimes.

How do I handle maintenance for the End-of-Line Side Load Packer?

For the End-of-Line Side Load Packer, perform regular diagnostic checks and updates. Ensure all packing equipment is functioning efficiently and make any necessary adjustments to maintain high performance. Implementing these practices will help maintain the reliability and efficiency of your Side Load Case Packer.

The XINTU Side Load Case Packer incorporates advanced technology to enhance the efficiency and reliability of your packaging operations. As an industry leader, XINTU ensures that each Side Load Packaging Machine is equipped with cutting-edge features.

Precision Engineering: Our Side Load Case Packer is meticulously engineered to handle various product sizes and shapes with high precision, ensuring consistent packing quality and minimizing product damage.

Automated Efficiency: The Automatic Side Load Packer employs sophisticated control systems and sensors to automate the entire packing process, reducing labor costs and increasing throughput. This high-speed Side Load Packing Equipment can efficiently manage large volumes, making it ideal for high-demand production lines.

Versatile Applications: The Side Entry Case Packer is designed to accommodate a wide range of packaging formats, from cartons to pouches. Its adaptability makes it suitable for diverse industries, including food and beverage, pharmaceuticals, and consumer goods.

Integrated Systems: The Side Load Carton Packer can seamlessly integrate with upstream and downstream equipment, forming a cohesive Side Load Case Packing System. This integration enhances the overall efficiency of the end-of-line packaging operations.

Robust Construction: Built with durability in mind, the Side Load Packing Equipment features robust materials and components that ensure long-term reliable performance even in demanding industrial environments.

User-Friendly Interface: The High-Speed Side Load Packer is equipped with an intuitive human-machine interface (HMI) that simplifies operation and troubleshooting. This interface allows for quick adjustments and minimal downtime, ensuring smooth and continuous operation.

Safety and Compliance: The End-of-Line Side Load Packer includes multiple safety features, such as emergency stops and protective enclosures, to ensure safe operation and compliance with industry standards.

By leveraging these advanced technologies, XINTU’s Side Load Case Packers provide a comprehensive and efficient solution for your packaging needs, delivering reliable performance and superior results.

Proper installation of the XINTU Side Load Case Packer is crucial to ensure optimal performance and longevity of the equipment. Follow these steps to seamlessly integrate the Side Load Packaging Machine into your production line:

1. Site Preparation

- Ensure that the installation site is level, clean, and free of obstructions.

- Verify that the site has the necessary electrical and air supply connections suitable for the Automatic Side Load Packer requirements.

2. Positioning the Equipment

- Carefully position the Side Entry Case Packer in the designated area, ensuring that there is adequate space around the machine for maintenance and operation.

- Align the Side Load Carton Packer with other equipment in the production line to ensure smooth product flow.

3. Electrical and Air Connections

- Connect the Side Load Packing Equipment to the electrical supply, ensuring that all connections comply with local electrical codes.

- Connect the machine to the compressed air supply, verifying that the air pressure meets the specifications of the High-Speed Side Load Packer.

4. Initial Setup and Calibration

- Power up the Side Load Case Packing System and follow the initial setup instructions provided in the user manual.

- Calibrate the machine sensors and actuators to ensure precise operation of the Side Load Packaging Machine.

5. Integration with Production Line

- Integrate the Side Load Case Packer with upstream and downstream equipment, such as conveyors and sealing machines.

- Test the synchronization between the End-of-Line Side Load Packer and other components to ensure seamless operation.

6. Safety Checks

- Conduct a thorough inspection of the machine’s safety features, including emergency stops and protective guards.

- Ensure that all safety protocols are in place and that operators are trained in the safe operation of the Automatic Side Load Packer.

7. Trial Run and Adjustments

- Perform a trial run with sample products to verify the performance of the Side Load Packing Equipment.

- Make necessary adjustments to the settings of the Side Loading Case Packer to optimize efficiency and product handling.

By following these steps, you can ensure that your XINTU Side Load Case Packer is installed correctly and integrated smoothly into your production line, providing reliable and efficient packaging solutions.

Yes, the XINTU Side Load Case Packer is designed to handle various product sizes and shapes efficiently. This Side Loading Case Packer is engineered to accommodate a wide range of packaging needs, making it highly versatile. The Side Load Packaging Machine can automatically adjust to different product dimensions, ensuring smooth and precise packing operations.

The Automatic Side Load Packer uses advanced technology to manage various product configurations, whether they are cartons, bottles, or irregularly shaped items. Its flexibility and adaptability make it an ideal choice for industries with diverse packaging requirements.

The Side Entry Case Packer is equipped with customizable settings and tools, allowing for quick changeovers and minimal downtime. This feature enhances productivity and ensures continuous operation in dynamic production environments.

With the Side Load Carton Packer, you can achieve high-speed packing while maintaining accuracy and consistency. The Side Load Packing Equipment is perfect for end-of-line applications, providing a seamless integration into existing production lines.

Overall, the High-Speed Side Load Packer and the comprehensive Side Load Case Packing System offer a reliable solution for handling different product sizes and shapes, ensuring efficient and effective end-of-line packaging.

Automated Loading

The Side Load Case Packer automates the loading process, ensuring efficient and precise packing operations.Versatile Packaging

This Side Loading Case Packer handles a variety of product sizes and shapes, making it a versatile solution for different industries.High-Speed Operation

As a High-Speed Side Load Packer, it delivers rapid packing speeds, increasing productivity and throughput.User-Friendly Interface

The Automatic Side Load Packer is equipped with an intuitive interface, simplifying operation and reducing training time.Robust Construction

The Side Load Carton Packer is built with durable materials, ensuring longevity and reliable performance in demanding environments.Seamless Integration

Easily integrates into existing production lines, enhancing the overall efficiency of your Side Load Case Packing System.Customizable Settings

This Side Entry Case Packer offers customizable settings to meet specific packaging requirements and ensure optimal performance.Safety Features

The Side Load Packing Equipment includes advanced safety features to protect operators and maintain a safe working environment.Compact Design

Its compact design allows for efficient use of space, making it ideal for facilities with limited floor space.End-of-Line Efficiency

Perfect for end-of-line packaging solutions, ensuring products are securely packed and ready for distribution.

Precision Engineering

The Side Load Case Packer is designed with precision engineering to handle products consistently and accurately, reducing errors in the packing process.Automated Control Systems

The Automatic Side Load Packer utilizes advanced PLC and touch screen control systems to maintain consistent packing parameters, ensuring uniformity across all packed cases.Flexible Product Handling

This Side Loading Case Packer can accommodate different product sizes and shapes, thanks to its versatile design, allowing it to maintain packing consistency regardless of product variations.High-Speed Operations

Equipped as a High-Speed Side Load Packer, it maintains high throughput without sacrificing accuracy, ensuring efficient and consistent packing.Quality Materials and Construction

Built with robust materials, the Side Load Carton Packer ensures long-term reliability and consistent performance even in demanding environments.Integrated Safety Features

The Side Load Packing Equipment includes comprehensive safety features, ensuring safe and consistent operation, preventing accidents that could disrupt the packing process.Comprehensive Monitoring and Adjustment

Operators can use the intuitive interface to monitor the packing process in real-time, making necessary adjustments to maintain consistency through the Side Load Case Packing System.End-of-Line Efficiency

As part of an End-of-Line Side Load Packer system, it seamlessly integrates with other equipment to ensure a smooth and consistent flow of products through the entire packaging process.

By leveraging these advanced features, the XINTU Side Entry Case Packer guarantees that each product is packed consistently, enhancing overall productivity and efficiency.

Integrating the XINTU Side Load Case Packer into your existing production line is a seamless process, thanks to its versatile design and advanced technology. Here's how you can achieve optimal integration:

Compatibility Assessment

Begin with a thorough compatibility assessment to ensure the Side Load Case Packer aligns with your current production line specifications and requirements.Modular Design

The Side Load Packaging Machine features a modular design, allowing for easy integration with minimal disruption to your existing setup. This ensures a smooth transition without extensive modifications.Automated Control Systems

Utilize the advanced PLC and touch screen controls of the Automatic Side Load Packer to synchronize with your production line's existing systems. This facilitates seamless communication and coordination between different machines.Flexible Configuration

The Side Entry Case Packer can be configured to handle various product sizes and shapes, making it adaptable to your specific packaging needs. Adjustments can be made to accommodate different packaging formats, ensuring efficient integration.High-Speed Operations

As a High-Speed Side Load Packer, it can match the pace of your existing production line, maintaining consistent throughput and minimizing bottlenecks.End-of-Line Compatibility

Designed as part of an End-of-Line Side Load Packer system, it integrates effortlessly with other end-of-line equipment, such as conveyors, palletizers, and wrapping machines, enhancing overall production efficiency.Technical Support and Training

XINTU offers comprehensive support and training to ensure your team can effectively operate the Side Load Case Packing System. This includes on-site assistance and detailed training sessions to maximize productivity.Remote Monitoring and Diagnostics

With remote access capabilities, the Side Load Carton Packer allows for continuous monitoring and diagnostics, enabling quick resolution of any integration issues and ensuring smooth operation.

By leveraging these features and strategies, you can seamlessly integrate the XINTU Side Load Packing Equipment into your existing production line, enhancing efficiency and productivity while minimizing downtime.

To operate the XINTU Side Load Case Packaging Machine efficiently, you need to ensure the following energy specifications:

- Power Supply: The machine operates on a 380V, 50/60Hz three-phase power supply.

- Air Pressure: It requires an air pressure of 5-6 kg/cm² to function optimally.

- Energy Consumption: Depending on the specific model and operational load, the machine's energy consumption can vary, but it is designed to be energy-efficient.

This Side Load Case Packer, also known as a Side Loading Case Packer or Automatic Side Load Packer, integrates seamlessly into your Side Load Packaging Machine system. It is engineered to work efficiently as part of a Side Load Case Packing System, providing high-speed, end-of-line packaging solutions. The Side Entry Case Packer and Side Load Carton Packer are built with advanced technology to ensure energy-efficient operation, making it an ideal choice for any industrial setup requiring reliable Side Load Packing Equipment.

The XINTU Side Load Case Packaging Machine is designed with robust safety features to ensure the safety of operators and maintain seamless operation. Key safety features include:

- Emergency Stop Buttons: Strategically placed emergency stop buttons are easily accessible to halt operations immediately in case of any emergency.

- Guarding and Safety Interlocks: The machine is equipped with guarding and safety interlocks to prevent access to moving parts during operation, enhancing operator safety.

- Automatic Shutdown: The machine includes automatic shutdown features that activate in the event of a malfunction or safety breach to prevent accidents.

- Safety Sensors: Advanced sensors detect obstructions or irregularities in the packing process, stopping the machine to avoid damage or injury.

- Controlled Access: Access to machine internals for maintenance is controlled and limited to authorized personnel only, ensuring that only trained individuals handle the machinery.

- Clear Signage and Indicators: The machine has clear signage and status indicators to keep operators informed about the machine's operational state and any potential hazards.

These features ensure that the XINTU Side Load Case Packer, also known as the Side Loading Case Packer or Automatic Side Load Packer, operates safely within any Side Load Packaging Machine system. Whether you are using the Side Entry Case Packer, Side Load Carton Packer, or other Side Load Packing Equipment, safety is paramount. This High-Speed Side Load Packer is part of the comprehensive Side Load Case Packing System designed for end-of-line packaging solutions.

Selecting the right Side Load Case Packer requires careful consideration of several factors to ensure it meets your packaging needs effectively. Here are key aspects to consider:

Product Compatibility:

- Ensure the Side Load Case Packer can handle the size, shape, and weight of your products.

- Suitable for items such as bottles, bags, cartons, and other packaged goods.

Speed Requirements:

- Assess your production line speed. A High-Speed Side Load Packer is ideal for high-volume operations.

- Determine the packer's throughput rate to match your production goals.

Flexibility:

- Look for a Side Loading Case Packer that can handle various packaging configurations.

- The machine should accommodate different case sizes and pack patterns.

Integration:

- Check if the Side Load Packaging Machine can be easily integrated into your existing production line.

- Ensure it works seamlessly with your End-of-Line Side Load Packer system.

Automation Level:

- Decide if you need a fully Automatic Side Load Packer or a semi-automatic option.

- Fully automated systems offer higher efficiency and consistency.

Space and Layout:

- Consider the physical space available in your facility.

- Ensure the Side Load Case Packing Equipment fits within your layout without hindering other operations.

Energy Efficiency:

- Evaluate the energy consumption of the Side Load Case Packing System to manage operational costs.

- Energy-efficient machines can reduce overall production expenses.

Safety Features:

- Ensure the machine includes essential safety features like interlocks and emergency stops.

- Safety is paramount in a Side Load Carton Packer to protect operators and equipment.

Maintenance and Support:

- Choose a machine with a good track record for reliability and low maintenance requirements.

- Ensure the supplier offers robust after-sales support for the Side Entry Case Packer.

Cost and ROI:

- Analyze the cost versus the expected return on investment (ROI).

- A higher upfront cost for a High-Speed Side Load Packer can be justified by long-term savings and efficiency gains.

By considering these factors, you can select the most suitable Side Load Case Packer for your specific packaging needs, ensuring optimal performance and efficiency in your production line.

There are several types of Side Load Case Packing machines available in the market, each tailored to meet specific packaging needs across various industries. Here are the primary types:

Standard Side Load Case Packer

- Efficient for medium-speed packaging of bottles, cartons, and bags.

- Provides reliable and consistent packing.

High-Speed Side Load Packer

- Designed for high-volume production environments.

- Ensures rapid packing rates suitable for large-scale operations.

Automatic Side Load Packer

- Fully automated system minimizing manual intervention.

- Ideal for reducing labor costs and enhancing packing precision.

Side Load Carton Packer

- Specially designed for packing cartons.

- Ensures secure and stable packaging for easy transportation.

Side Entry Case Packer

- Suitable for products that require horizontal packing.

- Commonly used in the food, beverage, pharmaceutical, and cosmetic industries.

Versatile Side Load Packing Equipment

- Handles a variety of packaging configurations.

- Compatible with both rigid and flexible packaging materials.

Side Load Tray Packer

- Packs products into trays efficiently.

- Ideal for products needing additional stability during transport.

Semi-Automatic Side Load Packer

- Combines manual loading with automatic packing.

- Offers flexibility for smaller production lines with varied products.

These machines can be part of a comprehensive Side Load Case Packing System in an End-of-Line Side Load Packer setup, ensuring seamless integration from product handling to final packaging. The Side Loading Case Packer technology enhances efficiency, reliability, and versatility in modern packaging operations.

The XINTU Side Load Case Packer offers several efficiency benefits, making it an ideal choice for modern packaging operations:

High-Speed Operation: This High-Speed Side Load Packer can process up to 360 cases per hour, significantly increasing throughput and reducing bottlenecks in your production line.

Versatility: The Side Load Case Packer can handle various product sizes and shapes, including bagged snacks and bottled drinks, ensuring compatibility with a wide range of packaging requirements.

Automation: As an Automatic Side Load Packer, it reduces manual intervention, minimizing labor costs and human error while maintaining consistent packing quality.

Integration: This Side Load Packaging Machine integrates seamlessly into existing production lines, offering a comprehensive End-of-Line Side Load Packer solution that optimizes the entire packaging process.

Space Efficiency: The compact design of the Side Load Carton Packer makes it suitable for facilities with limited floor space, ensuring efficient use of available space.

Reliability: With advanced features and robust construction, this Side Entry Case Packer ensures minimal downtime and reliable performance, enhancing overall productivity.

By incorporating the XINTU Side Load Case Packer, you can achieve efficient, high-speed, and reliable packaging operations, tailored to meet diverse industry needs.

XINTU offers several models of Side Load Case Packers, each designed to meet varying production needs. Here are the production capacities for different models:

Standard Side Load Case Packer:

- Capacity: Up to 200-360 cases per hour

- Applications: Suitable for standard packaging operations, including bagged snacks and boxed products.

High-Speed Side Load Case Packer:

- Capacity: Up to 400-600 cases per hour

- Applications: Ideal for high-demand environments such as beverage bottling plants and large-scale food production.

Customizable Side Load Case Packer:

- Capacity: Varies based on customization, typically ranges from 250-450 cases per hour

- Applications: Tailored to specific industry requirements, allowing for flexibility in handling different product sizes and shapes.

These models ensure that whether you need standard, high-speed, or customizable packing solutions, XINTU has a Side Load Case Packer that fits your production capacity needs, ensuring efficiency and reliability in your packaging processes.

Optimizing the efficiency of a Side Load Case Packer involves several strategic steps to ensure maximum performance and minimal downtime. Here are some key strategies:

Regular Maintenance:

- Perform scheduled maintenance to keep the machine in top working condition.

- Replace worn parts promptly to avoid unexpected breakdowns.

- Lubricate moving parts regularly to reduce friction and wear.

Automation Integration:

- Utilize an Automated Packaging Machine to streamline the packing process.

- Implement a Case Packing System that integrates seamlessly with other production line equipment.

- Use an End-of-Line Side Load Packer to automate the final stages of packing, reducing manual labor.

Advanced Technology:

- Incorporate advanced sensors and control systems for precise operation.

- Use a High-Speed Side Load Packer to increase throughput.

- Employ a Secondary Packaging Equipment system that adapts to various product sizes and shapes.

Operator Training:

- Train staff thoroughly on the operation and troubleshooting of the Side Load Packaging Machine.

- Regularly update training to include new features and technologies.

- Encourage continuous learning to keep operators proficient and efficient.

Optimize Workflow:

- Arrange the production line to minimize bottlenecks and streamline product flow.

- Implement a Carton Packing Line to ensure products are packed efficiently and correctly.

- Use an Automatic Side Load Packer to automate repetitive tasks, increasing overall efficiency.

Monitoring and Analytics:

- Use data analytics to monitor machine performance and identify areas for improvement.

- Set up alerts for any deviations from normal operation to address issues promptly.

- Regularly review performance metrics to optimize the High-Speed Side Load Packer's efficiency.

By focusing on these strategies, you can significantly enhance the efficiency of your Side Load Case Packing System, ensuring consistent and reliable packaging operations.

Using a Side Load Case Packer can present several challenges. Here are some common issues and troubleshooting tips to keep your packaging line running smoothly:

Jammed Cases

- Cause: Cases can become jammed due to misalignment or improper case size.

- Solution: Ensure that cases are correctly sized and aligned before entering the machine. Regularly clean the machine to remove debris that might cause jams.

Inconsistent Packing

- Cause: Inconsistent packing can be caused by variations in product size or improper machine settings.

- Solution: Adjust the machine settings to accommodate product variations. Use precise sensors and control systems to maintain consistent packing.

Product Damage

- Cause: Damage can occur if the machine settings are too aggressive or if products are not properly secured.

- Solution: Calibrate the machine to handle products gently. Secure products correctly before they enter the packer.

Machine Downtime

- Cause: Downtime can be due to mechanical failures or lack of regular maintenance.

- Solution: Implement a regular maintenance schedule. Replace worn-out parts promptly and keep spare parts on hand.

Misfeeds

- Cause: Misfeeds can happen due to improper loading or faulty feed mechanisms.

- Solution: Check the feed mechanisms for any faults and ensure products are loaded correctly. Regularly inspect and maintain feed components.

Sensor Failures

- Cause: Sensors can fail due to dust, debris, or electrical issues.

- Solution: Clean sensors regularly to remove dust and debris. Check electrical connections and replace faulty sensors as needed.

Integrated Keywords

- Side Load Case Packer: Ensure proper alignment and regular maintenance to avoid common issues.

- Side Loading Case Packer: Adjust machine settings to handle product variations and prevent inconsistent packing.

- Side Load Packaging Machine: Regular cleaning and maintenance are essential to prevent jams and downtime.

- Automatic Side Load Packer: Use precise sensors to maintain consistent packing and handle products gently to avoid damage.

- Side Entry Case Packer: Implement a regular maintenance schedule and replace worn-out parts to minimize downtime.

- Side Load Carton Packer: Check feed mechanisms and load products correctly to avoid misfeeds.

- Side Load Packing Equipment: Clean sensors regularly to ensure proper operation and avoid sensor failures.

- High-Speed Side Load Packer: Monitor and adjust machine settings for high-speed operations to ensure efficiency.

- Side Load Case Packing System: Use advanced control systems to maintain consistent packing and prevent common issues.

- End-of-Line Side Load Packer: Ensure all components are properly maintained and calibrated for optimal performance.

By addressing these common issues with proactive maintenance and precise machine settings, you can ensure your Side Load Case Packer operates efficiently and reliably.

Effective training is essential to ensure that staff can operate a Side Load Case Packer safely and efficiently. Here are key steps to guide you through the training process:

Step 1: Comprehensive Safety Orientation

Purpose: Familiarize staff with the basic safety protocols and the specific safety features of the Side Load Case Packer.

- Highlight Safety Features: Explain the safety interlocks, emergency stop buttons, and any other safety mechanisms.

- Safety Gear: Ensure all staff are aware of and use the required personal protective equipment (PPE).

Step 2: Detailed Operational Training

Purpose: Teach the operational steps involved in using the Side Load Case Packer, ensuring that each step is clearly understood.

- Machine Components: Walk through the main components of the Side Load Case Packer, including the control panel, loading area, and packing mechanism.

- Operational Sequence: Demonstrate the step-by-step process of operating the machine from start to finish.

Step 3: Hands-On Practice

Purpose: Allow staff to practice operating the machine under supervision to build confidence and competence.

- Supervised Practice: Provide hands-on sessions where staff can operate the machine under the supervision of experienced operators.

- Simulated Scenarios: Create different scenarios to practice handling various products and troubleshooting common issues.

Step 4: Regular Maintenance Training

Purpose: Ensure staff can perform routine maintenance and troubleshooting to keep the machine in optimal condition.

- Maintenance Tasks: Train staff on daily, weekly, and monthly maintenance tasks.

- Troubleshooting: Teach how to identify and fix common issues to minimize downtime.

Step 5: Continuous Education and Refresher Courses

Purpose: Keep staff updated on new safety protocols and operational techniques.

- Refresher Courses: Schedule regular refresher courses to revisit key safety and operational procedures.

- Updates and Upgrades: Inform staff of any updates or upgrades to the machinery and incorporate these into training sessions.

Key Terms for Safe Operation

- Side Load Case Packer: Learn the specific operational steps and safety features.

- Side Loading Case Packer: Understand the loading procedures and safety precautions.

- Side Load Packaging Machine: Gain knowledge of all machine components and their functions.

- Automatic Side Load Packer: Practice automated functions and emergency stop protocols.

- Side Entry Case Packer: Familiarize with entry points and case handling techniques.

- Side Load Carton Packer: Ensure correct carton sizes and secure loading.

- Side Load Packing Equipment: Maintain equipment regularly to prevent breakdowns.

- High-Speed Side Load Packer: Operate at high speeds with an emphasis on safety.

- Side Load Case Packing System: Integrate safely with existing production lines.

- End-of-Line Side Load Packer: Follow end-of-line safety procedures and product handling.

By following these steps, you ensure that your staff can operate the Side Load Case Packer safely and efficiently, contributing to a smooth and productive packaging process.

Side Load Case Packers have seen significant technological advancements in recent years, enhancing their efficiency, flexibility, and reliability. Here are some of the latest innovations:

1. Advanced Robotics Integration

The integration of advanced robotics has transformed the Side Load Case Packer, offering precise and consistent case loading with minimal human intervention. This includes:

- High-Speed Robotics: Robots capable of handling high-speed operations, ensuring faster and more accurate case packing.

- Adaptive Robotics: Robots that can adapt to various product sizes and shapes, enhancing the versatility of the packing process.

2. Intelligent Control Systems

Modern Side Load Case Packers are equipped with intelligent control systems that enhance operational efficiency and ease of use.

- PLC and HMI Integration: Programmable Logic Controllers (PLCs) combined with Human Machine Interfaces (HMIs) provide intuitive control and monitoring of the packing process.

- IoT Connectivity: Internet of Things (IoT) technology enables real-time monitoring and remote troubleshooting, reducing downtime and improving maintenance efficiency.

3. Enhanced Flexibility and Customization

These machines now offer greater flexibility to handle a variety of packaging formats and sizes without extensive reconfiguration.

- Quick Changeover Mechanisms: Features like tool-less changeovers and adjustable guides allow for rapid transition between different product lines.

- Customizable Packing Patterns: Ability to customize packing patterns and configurations to meet specific product and packaging requirements.

4. Energy Efficiency

New advancements focus on reducing energy consumption while maintaining high performance.

- Energy-Efficient Motors: Use of high-efficiency motors and drives to lower energy usage.

- Eco-Friendly Operations: Implementation of energy-saving modes and components that minimize power consumption during idle times.

5. Enhanced Safety Features

Safety is a crucial aspect of modern Side Load Case Packers, ensuring the protection of operators and the integrity of the packed products.

- Advanced Safety Interlocks: Safety interlocks and sensors prevent accidental operation and ensure the machine operates only under safe conditions.

- Comprehensive Guarding Systems: Full guarding with interlocked doors and light curtains enhance operator safety during machine operation and maintenance.

Key Terms Highlighted:

- Side Load Case Packer: Main focus of technological advancements.

- Side Loading Case Packer: Enhanced robotics and control systems.

- Side Load Packaging Machine: Improved flexibility and customization.

- Automatic Side Load Packer: Intelligent control systems for ease of use.

- Side Entry Case Packer: Increased operational safety features.

- Side Load Carton Packer: Energy-efficient operations.

- Side Load Packing Equipment: Enhanced productivity and efficiency.

- High-Speed Side Load Packer: High-speed robotics integration.

- Side Load Case Packing System: Comprehensive system improvements.

- End-of-Line Side Load Packer: Enhanced end-of-line packaging solutions.

By leveraging these technological advancements, XINTU’s Side Load Case Packers deliver superior performance, reliability, and efficiency, making them an ideal choice for modern packaging operations.