In today’s competitive manufacturing world, efficiency, precision, and reliability are key to staying ahead. At XINTU Automation, we understand your need to optimize every aspect of your production line, which is why we’ve developed our servo-driven top load case packer to transform your packaging process. If you’re looking for an automatic case packer that improves speed, reduces costs, and ensures consistent quality, then you’re in the right place.

What is a Servo-Driven Top Load Case Packer?

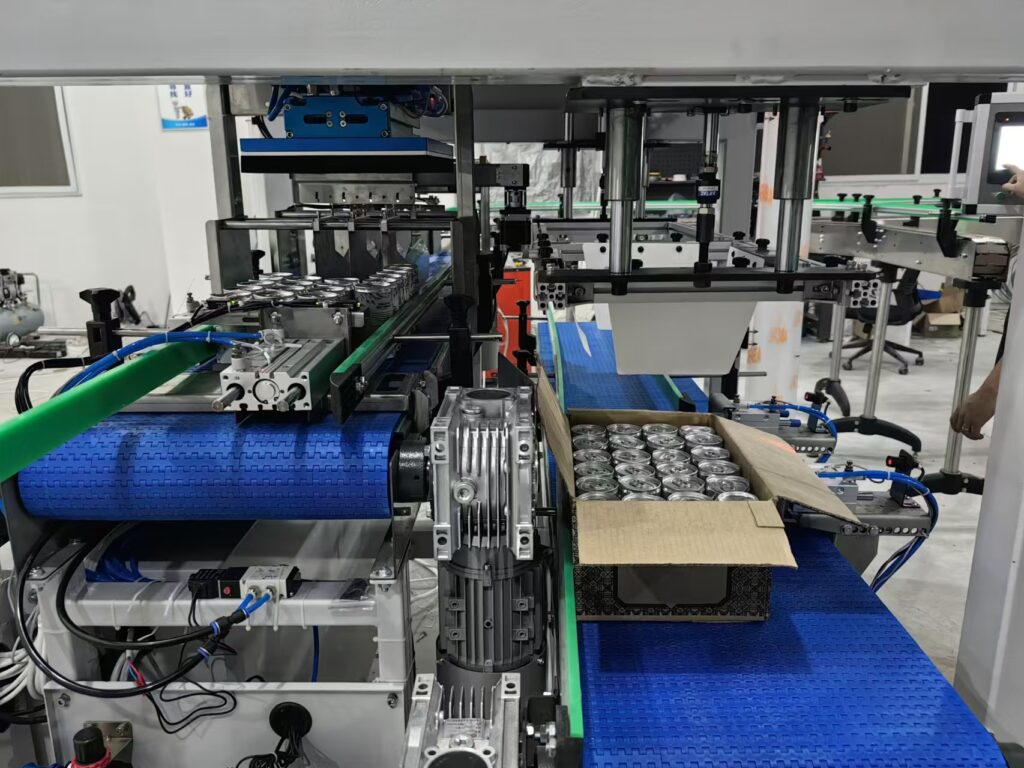

A servo-driven top load case packer uses advanced servo motors to precisely control the grabbing, placing, and packing of products into cartons. This high-speed packaging solution is designed for industries that require consistent, efficient, and precise packing, such as pharmaceuticals, food & beverage, and cosmetics. By leveraging end-of-line packaging automation, XINTU’s case packer provides superior control and flexibility compared to traditional machines.

Here’s Why You Need One:

If you’ve struggled with manual packing errors or inconsistent product placement, our customizable case packer is the solution. It’s designed to optimize your line, reduce waste, and increase throughput—all while maintaining high precision.

Key Benefits of XINTU’s Servo-Driven Top Load Case Packer

1.Unmatched Precision & Stability

Let’s face it: the last thing you want is damaged products due to poor packing. Our servo-driven case packer uses high-performance servo motors that ensure every bottle, box, or jar is packed securely and safely. This precise control minimizes errors, reduces product waste, and guarantees consistent quality—every single time.

- Perfect for fragile products like cosmetics or pharmaceutical bottles that require gentle handling.

- Ensures stable product placement, preventing damage during transit.

2. High-Speed, Efficient Operation

We know speed matters. This machine can pack 10 cartons per minute, with each carton holding 12 bottles/bags/jars/boxes—that’s 120 bottles/bags/jars/boxes per minute! Imagine what that kind of efficiency can do for your production line.

- Increase your output without compromising on quality.

- Meet tight deadlines and high-volume demands effortlessly.

One of the greatest advantages of our system is its customizable design. Whether you’re packing glass bottles, plastic jars, or cartons, our pick and place case packer adapts to your specific needs with minimal adjustments.

- Ideal for industries with frequently changing product lines.

- Quickly adjust settings to pack various product types without downtime.

- Perfect for industries where product lines change frequently.

- Can handle various packaging formats, from food & beverage to pharmaceutical packaging.

4. Compact Design to Save Space

Running out of floor space? Our compact top load case packer is designed to fit seamlessly into existing setups, making it ideal for facilities with limited space. You can easily integrate it with other equipment like case erectors, sealers, and robotic palletizers.

- Saves valuable production space while maximizing efficiency.

- Ideal for end-of-line packaging automation in small to medium-sized factories.

5. Intelligent Automation & Control

What sets our servo-driven top load case packer apart is its smart control system. With real-time monitoring and adjustments, it ensures every pack is perfect. The system can automatically adjust to different product sizes, ensuring that even the most delicate items are packed securely.

- Reduces manual intervention, ensuring consistent packaging quality.

- Optimizes production with automated packaging solutions.

Industry Applications: Where Our Case Packers Excel

Our top load case packers are designed to handle diverse packaging needs across various industries:

Pharmaceuticals

Worried about safely packing glass vials or delicate blister packs? Our pharmaceutical case packer ensures each product is securely packed, reducing breakage and ensuring compliance with industry standards.

Cosmetics & Personal Care

From skincare bottles to makeup palettes, our pick and place case packer handles delicate items with care, ensuring they reach your customers in perfect condition.

Food & Beverage

Our high-speed case packer is perfect for packing bottled drinks, snacks, and other consumables. Its speed and precision ensure your products remain fresh and secure during transport.

Household Products

Whether it’s detergents, pet food, or cleaning supplies, our machine can handle a variety of packaging formats, making it perfect for dynamic end-of-line packaging automation.

Success Stories: How Our Clients Have Transformed Their Operations

Let me share a few examples with you. One of our Beverage Industry clients was struggling with manual packing that was slowing down their line and causing product damage. After integrating our servo-driven top load case packer, they saw a 30% increase in productivity and reduced their labor costs by nearly 40%.

Another client in the Dairy industry wanted to switch to automated packaging to handle their increasing demand. Our machine not only met their speed requirements but also ensured that every product was packed beautifully, enhancing their brand’s reputation.

Frequently Asked Questions (FAQ)

Q1: Can your case packer handle different carton sizes?

- A: Absolutely! Our machine is designed for flexibility. You can easily adjust the settings to accommodate various carton sizes and shapes.

Q2: Is training provided after installation?

- A: Yes, we offer comprehensive training and ongoing support to ensure your team is fully comfortable operating the equipment.

Q3: How long does it take to install the machine?

- A: Typically, installation takes just a few days, and our team is available to support you every step of the way.

Q4: How quickly can I expect to see ROI?

- A: Most clients see a return on investment within a few months, thanks to increased efficiency and reduced labor costs.

Why Choose XINTU Automation?

We’re not just another equipment supplier—we’re your partner in automation. With over 20 years of industry experience, we understand the challenges you face and are committed to helping you overcome them.

- Comprehensive Support: From installation and training to ongoing maintenance, we’ve got you covered.

- Custom Solutions: We tailor our machines to fit your specific needs, ensuring that you get the most out of your investment.

- Proven Track Record: Trusted by clients across North America, Australia,Russian,Europe, South America,Mexico and Asia, we’ve helped businesses of all sizes achieve their automation goals.

Ready to Take Your Packaging Line to the Next Level?

If you’re tired of slow, inefficient packaging processes and want a solution that can truly transform your operations, it’s time to invest in XINTU’s servo-driven top load case packer.

📧 Email: mary@xintuequipment.com

📞 Phone: +8615136164937

🌐 Visit Our Website: https://xintuequipment.com

Let’s Connect

Don’t let inefficiencies hold you back. Let’s discuss how we can help you streamline your packaging line, boost your production speed, and improve your bottom line. Reach out today to schedule a consultation!