In the fast-paced world of manufacturing and logistics, efficient packaging solutions are essential for ensuring product integrity, optimizing storage, and streamlining transportation. One solution that stands out is the Wrap Around Case Packer. Known for its space-saving design and ability to provide superior stability, this machine is becoming a must-have for industries ranging from food and beverage to cosmetics and consumer goods.

In this blog, we’ll explore how Wrap Around Case Packers save space, improve packaging stability, and help businesses optimize their packaging processes.

What Are Wrap Around Case Packers?

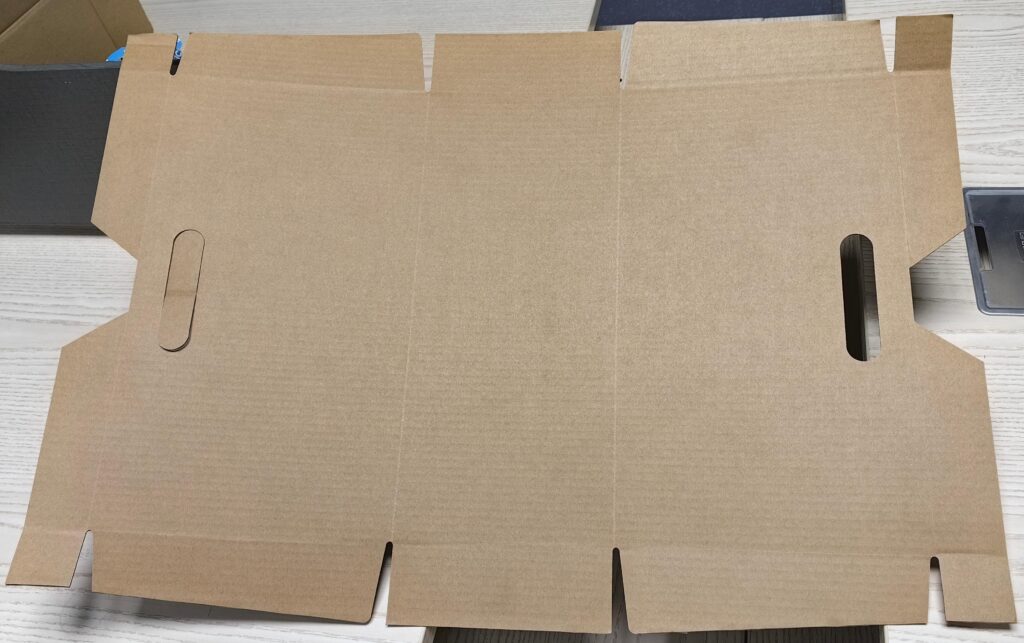

A Wrap Around Case Packer is a type of automated packaging machine that wraps a flat cardboard sheet around a group of products to form a tight, secure case. Unlike traditional top-load or side-load case packers, this machine creates a custom-fit package, eliminating unnecessary voids and reducing material waste.

Key Benefits of Wrap Around Case Packers

1. Space-Saving Design 🛠️

One of the most significant advantages of Wrap Around Case Packers is their compact footprint. By integrating multiple functions—such as case forming, product grouping, and sealing—into one streamlined process, these machines minimize the space required on the production floor. This is particularly beneficial for factories with limited space.

2. Improved Stability for Transportation 🚚

The wrap-around method creates a snug fit around the products, ensuring they remain stable within the case during shipping. Whether it’s fragile glass bottles, flexible pouches, or rigid cartons, the tight packaging minimizes movement, reducing the risk of product damage.

3. Versatility Across Product Types 🌐

Wrap Around Case Packers can handle a wide range of product shapes and sizes, including:

- Bottled beverages: Glass or plastic bottles of water, beer, or sauces.

- Canned goods: Metal cans of soups, vegetables, or pet food.

- Boxed products: Rigid cartons for pharmaceuticals, cosmetics, and small appliances.

- Flexible packaging: Stand-up pouches for snacks, coffee, or pet food.

4. Material Efficiency 💡

Unlike traditional case packing methods, wrap-around systems use flat sheets of cardboard to create cases. This reduces material waste and packaging costs while still providing strong, durable packaging.

5. High-Speed Operation 🚀

Modern Wrap Around Case Packers can process up to 15-25 cases per minute, depending on the product and configuration. This speed ensures businesses can meet growing production demands without sacrificing quality.

How Wrap Around Case Packers Save Space

Wrap Around Case Packers eliminate the need for separate case forming, loading, and sealing equipment by integrating all these functions into one compact machine. Here’s how they help save space:

- Multi-Functionality: Combines forming, packing, and sealing into one unit.

- Reduced Material Storage: Uses flat cardboard sheets, which take up less storage space than pre-formed cases.

- Efficient Layout: Designed to fit seamlessly into existing production lines without requiring extensive modifications.

Enhancing Packaging Stability with Wrap Around Case Packers

The snug, wrap-around design significantly enhances packaging stability by:

- Reducing Movement: Products are tightly secured, minimizing movement within the case.

- Supporting Fragile Items: Ideal for glass bottles or delicate products that require extra protection.

- Ensuring Stackability: Cases are uniform and compact, making them easier to stack securely during storage and transportation.

Use Case: A Beverage Manufacturer’s Success Story

One of our clients, a leading bottled beverage manufacturer, faced challenges with inconsistent packaging that led to product damage during shipping. After implementing our Wrap Around Case Packer, they achieved:

- 40% reduction in material costs due to efficient use of flat cardboard sheets.

- 30% improvement in packaging speed, processing up to 20 cases per minute.

- Significant reduction in shipping damage, ensuring products reached customers in perfect condition.

Industries That Benefit from Wrap Around Case Packers

1. Food & Beverage Industry:

- Bottled water, soft drinks, and alcoholic beverages.

- Canned goods like soups, vegetables, and pet food.

2. Pharmaceuticals & Health Products:

- Boxed medicines and health supplements.

- Rigid containers for medical supplies.

3. Cosmetics & Personal Care:

- Bottled skincare products, shampoos, and lotions.

- Gift sets for promotional packaging.

4. Household & Chemical Products:

- Cleaning agents in bottles or pouches.

- Automotive care products like oils and sprays.

5. Consumer Electronics:

- Small gadgets, chargers, and boxed accessories.

FAQs About Wrap Around Case Packers

1. What makes Wrap Around Case Packers better than traditional packers?

They provide a snug fit around products, ensuring better stability, reducing material waste, and offering a compact machine design.

2. Can they handle fragile products?

Yes! Wrap Around Case Packers are ideal for delicate items like glass bottles or fragile boxed products.

3. Are they suitable for mixed product lines?

Absolutely. These machines are versatile and can handle various product types and sizes with quick changeovers.

4. How fast can they operate?

They can pack between 15-25 cases per minute, depending on the configuration and product.

Why Choose XINTU Automation?

At XINTU Automation, we specialize in providing customized Wrap Around Case Packers that meet the unique needs of your business. With over a decade of experience in automated packaging, we ensure you get a solution that improves efficiency, reduces costs, and enhances product stability.

Let’s Optimize Your Packaging Process

If you’re ready to save space, improve stability, and streamline your packaging process, let’s connect!

📧 Email: Mary@xintuequipment.com

📞 Call Us: +8615136164937

🌐 Visit Our Website: https://xintuequipment.com