Automatic Case Packers Custom Design and Manufacturing

Case Packers

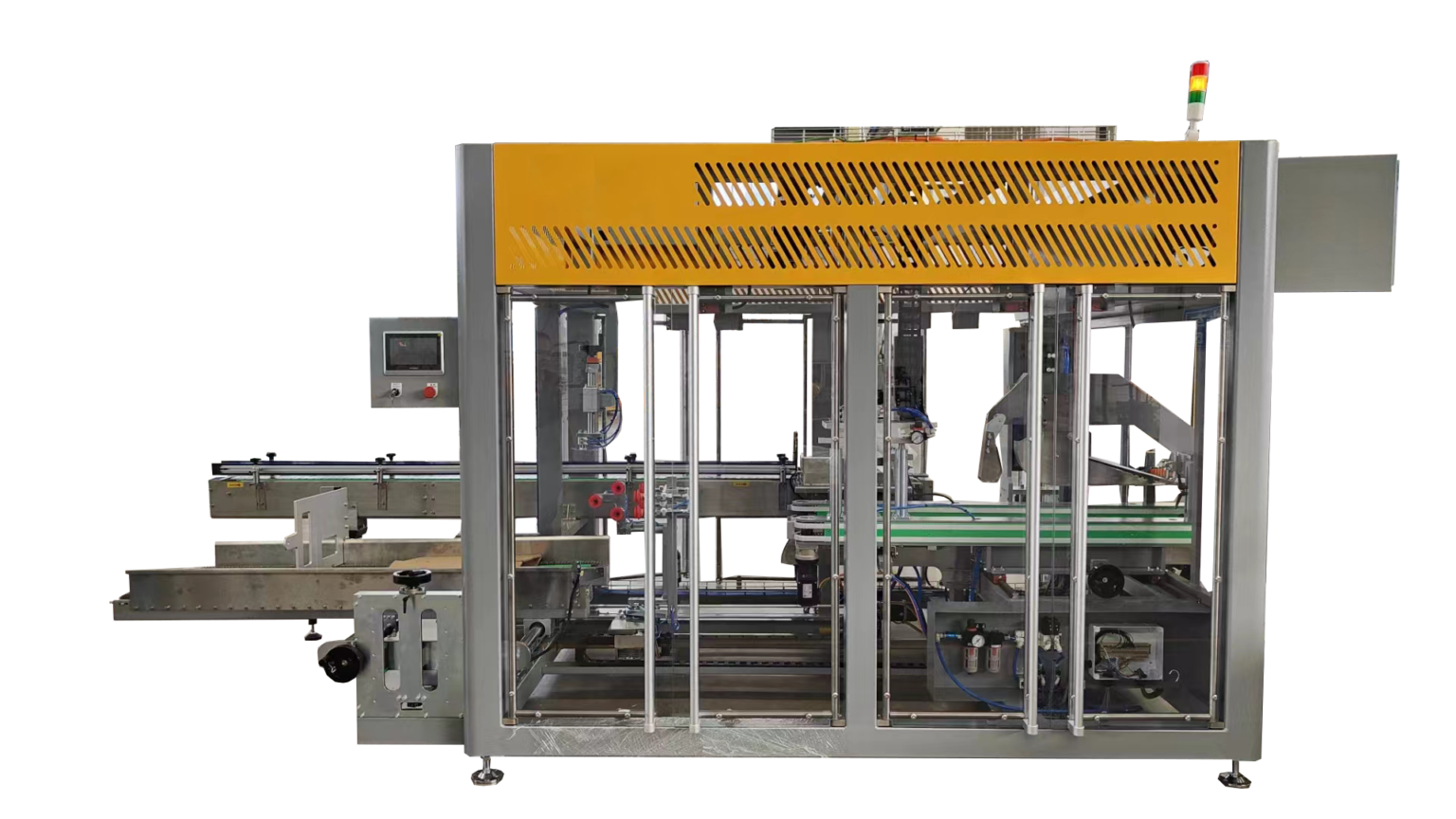

XINTU offers a diverse range of case packers, including wrap-around, side load case packer, top load case packer, drop type case packer, vertical case packer, robotic case packer, pick and place case packer, and horizontal case packer.

What sets XINTU apart from other manufacturers is our seamless integration with case erectors and sealers, providing a cohesive and efficient packaging line. Our case packing machines are available in multiple packing configurations and designed to meet a variety of packaging needs.

Your Trusted Partner for Customized Packaging Solutions

With XINTU, you gain a partner with decades of expertise in packaging equipment and robotic integration. We understand that your packaging needs are unique, influenced by product type, speed requirements, pack patterns, and space constraints. That’s why we provide tailored solutions rather than a one-size-fits-all approach.

At XINTU, we leverage our extensive experience in manufacturing various custom case packing machines and integrating robotic applications. Our automated systems are designed to be enhance your packing operations, ensuring peak performance while minimizing downtime,cost-effective, ensuring high return on investment.

Whether you need a quote or want to explore options for your end-of-line operation, XINTU has the solution for you.

Start your journey with XINTU:

Fill out this contact form to get a solution that suits your packaging needs.

Achieve Maximum ROI with XINTU Automated Case Packers

Automated case packers are essential for reducing labor costs, including wages, recruitment, training, and potential injuries, while significantly boosting your throughput rate and quality output.

XINTU provides a comprehensive selection of case packers, including top load, wrap-around, side load, drop load, and robotic models, each designed to fit your unique packaging requirements.

Our range of case packers delivers unmatched flexibility and performance, catering to different product types and packaging styles. These machines ensure efficient operation and smooth integration into your production process, with each type offering distinct advantages tailored to optimize your packaging workflow. Whether you need precision, speed, or adaptability, XINTU has the right solution for your packaging challenges.

Each type of case packer offers specific benefits:

Top Load Case Packer

Side Load Case Packer

Drop Load Case Packer

Wrap Around Case Packer

Pick and Place Case Packer

Robotic Case Packer

Our packaging machines are equipped with an advanced human-machine interface (HMI), providing an intuitive, user-friendly experience that simplifies operation and troubleshooting. This reduces training costs and enhances operational efficiency. Additionally, remote access capabilities allow for quick, efficient service support without the need for in-person visits, ensuring continuous productivity and reliability.

Contact Us to Tailor Your Packing Application

Looking for a custom case packer that fits your specific product needs? Let XINTU create the perfect solution for you.

- Product Handling and Transfer: Efficiently sorting, orienting, and collating products to streamline your packing process.

- Pack Pattern Formation: Creating vertical and/or horizontal loading techniques, including interleaved, stacked, on edge, on end, rainbow or variety packs, bulk, and shelf-ready configurations.

- Advanced Conveying Technologies: Utilizing servo collators, diverting systems, tabletop and mat top conveyors, and independent cart technology to handle various product types, speeds, and pack configurations.

- Environmental Adaptability: Meeting stringent requirements for washdown, freezing, dusty, hot, or humid environments, ensuring reliability and performance in any setting.

- Robotic Expertise: Leveraging articulated arm, delta, and SCARA robots to provide the best fit for your application based on capability, flexibility, and cost.

- Vision Guidance and Line Tracking: Inspecting, detecting, sorting, and manipulating products in real-time to balance the load between robots and ensure precise handling.

- Custom End-of-Arm Tools: Developing application-specific tools and automatic tool changeover to enhance efficiency and adaptability.

- Robotic Simulation: Using simulation for concept testing and visualization to validate and optimize your packing solutions.

- User-Centric Design: Implementing a Human-Machine Interface (HMI) that supports quick learning and efficient use, reducing training costs and maximizing uptime.

Explore Our Video Library

Collaborate with the Experts in case packers

At XINTU, our capabilities highlight the skills and advanced tools we bring to overcome the most unique picking and packing challenges

- Robust Machine Design: Expect a rugged construction that ensures durability and long equipment life in continuous 24/7 operations.

- Uniform User Interface: Enjoy a consistent and intuitive interface across all our erecting, packing, sealing, and palletizing equipment, simplifying your operations.

- Comprehensive Support: Count on our extensive sales, aftermarket, and service support to meet your needs at every stage.

- Fast Delivery: Benefit from industry-leading lead times for quicker delivery and shorter down-payment cycles, keeping your production on track.

- Advanced HMI: Enhance workforce efficiency with the most advanced Human Machine Interface (HMI) in the secondary packaging industry, ideal for supporting high-turnover labor.

- Proven Reliability: Trust in solutions backed by decades of expertise in erecting, packing, and sealing.

- Project Management Excellence: Depend on our dedicated project managers to ensure visibility, timely delivery, and budget adherence.

- 24/7 Support: Always lean on us for continuous live service support, ensuring your operations run smoothly without interruptions.