About Us

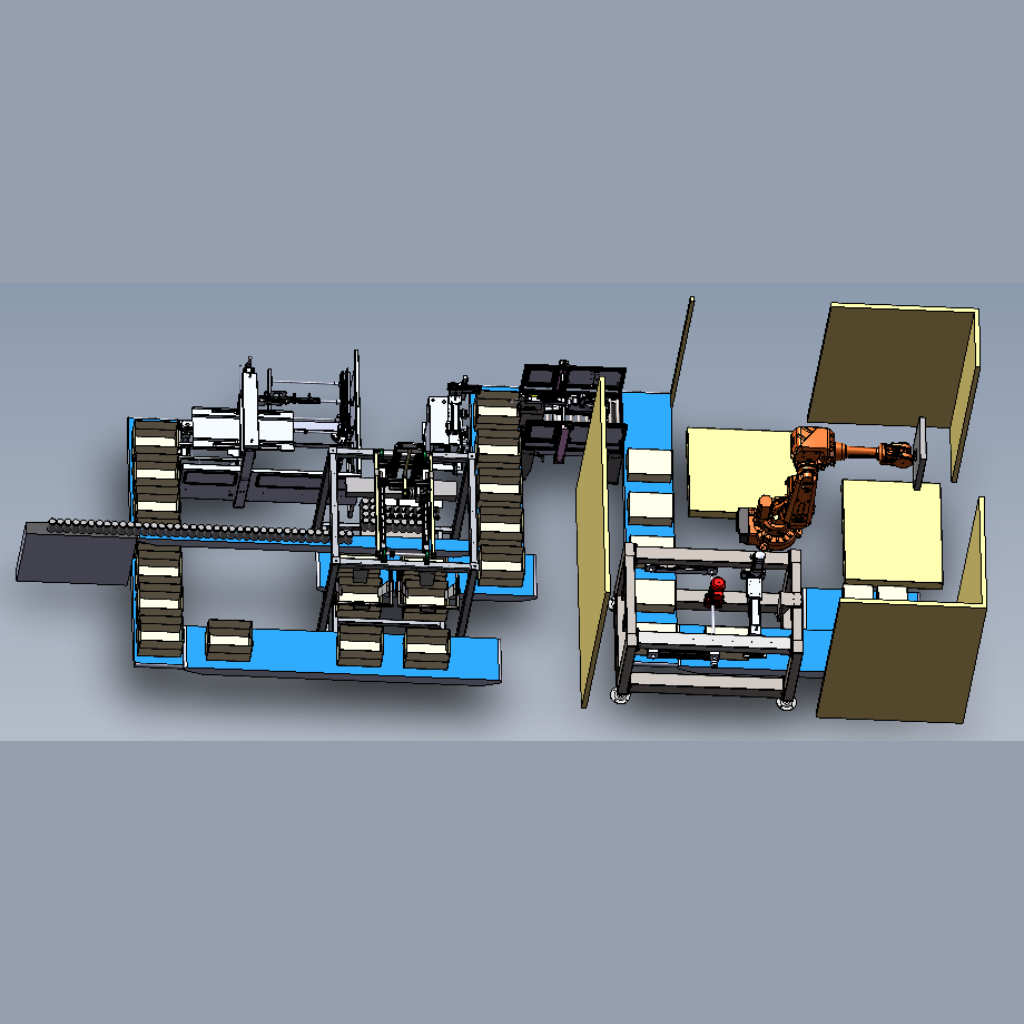

Custom TurnkeyEnd-Of-Line Packaging Solutions

Delivering Excellence and Efficiency in Global Packaging Systems

Redefining End-of-Line Packaging Solutions

Transforming Packaging Processes with Precision and Innovation

For over two decades, XINTU Automation has been at the forefront of the packaging industry, providing innovative and customized end-of-line packaging systems to meet the diverse needs of businesses worldwide. As a trusted manufacturer based in China, we specialize in case packaging machines, palletizer machines, and customized case packaging lines designed to enhance your production efficiency and reliability.

Innovative Engineering

Our mission is to deliver state-of-the-art packaging machines and systems that enhance productivity and ensure reliability across various industries. We strive to integrate the latest technological advancements into our products to provide superior performance and efficiency.

Customized Solutions

We are committed to offering tailored case packaging solutions that meet the unique requirements of each client. By understanding their specific challenges and objectives, we design and manufacture equipment that optimizes their packaging processes.

Global Reach, timely Support

With a strong global presence, we aim to support businesses worldwide with our comprehensive case packaging systems. Our extensive online network ensures that we provide timely and effective support whenever they needed.

Sustainable Practices

We are dedicated to promoting sustainability in packaging machines. Our solutions are designed to reduce waste, enhance energy efficiency, and support environmentally friendly practices in the packaging industry.

The Case Packaging Machines Supplier Story In China

XINTU Origin:

XINTU Automation was established to address the growing demand for efficient and reliable packaging solutions. With a dedicated team of engineers and state-of-the-art manufacturing facilities, we quickly became a preferred partner for businesses looking to optimize their packaging processes.

Operating out of a small Zhengzhou factory with 10 employees, XINTU Automation initially focused on semi-automated carton packaging and case packing machines.

Initial Triumphs:

Under the leadership of Jinwu Li, XINTU Automation rapidly gained traction in the packaging machinery market. By 2015, XINTU had secured over 20% of the domestic market share, demonstrating exceptional growth and industry influence.

In 2020, Mary Ma joined XINTU as the Global Expansion Manager. Utilizing her deep knowledge of international markets and strategic insight, Mary led the charge into new territories. Her efforts resulted in the successful establishment of advanced manufacturing facilities across China, solidifying XINTU’s reputation as a premier provider of end-of-line packaging solutions.

These strategic moves not only strengthened XINTU’s market presence but also expanded their ability to deliver innovative, reliable, and customized case/tray packaging solutions to a diverse global clientele. The company’s commitment to quality and customer satisfaction has driven its continued success and growth in the highly competitive packaging industry.

Growth and Expansion:

Our innovative approach and relentless pursuit of excellence allowed us to expand our product line and global reach. Today, XINTU serves customers across North America, Australia, South America, Europe, Russia, Turkey, and the Middle East,etc., providing tailored solutions for industries ranging from food and beverage to personal care and pharmaceuticals.

EXPLORE FURTHER

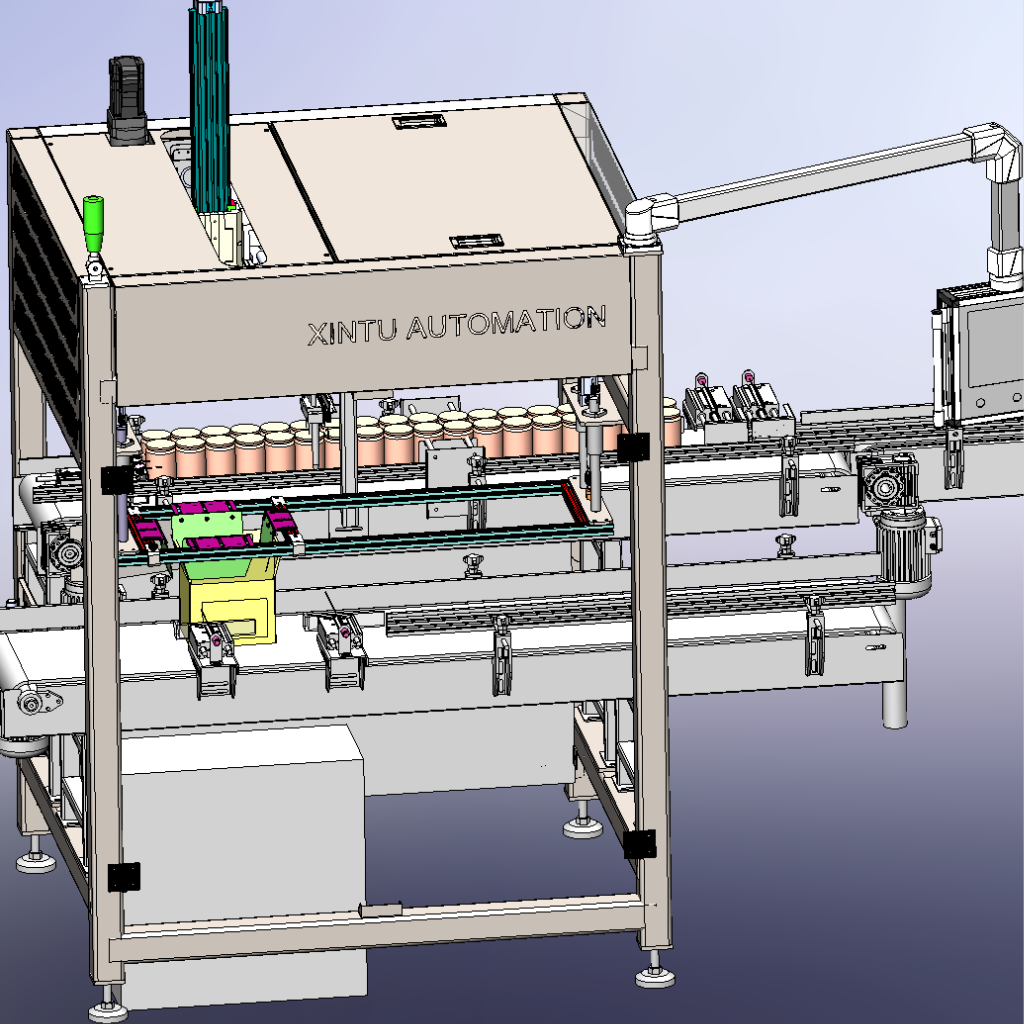

Construction Steps of a Case Packaging Machine

Conceptual Design

Purpose: Develop initial design concepts.

Process: Engineers create conceptual designs using CAD software. These designs include the basic layout of the machine, the types of movements needed, and initial considerations for automation and control systems.

Detailed Engineering Design

Purpose: Finalize the design and prepare for manufacturing.

Process: Detailed engineering drawings and models are created, specifying every component’s dimensions, materials, and tolerances. This step also involves the selection of appropriate sensors, actuators, and control systems.

Prototype Development (if required)

Purpose: Test and validate the design.

Process: A prototype of the machine or its critical components is built. The prototype is tested for functionality, reliability, and performance. Feedback from these tests is used to refine the design.

Component Manufacturing

Purpose: Produce individual parts of the machine.

Process: Using the detailed engineering drawings, components are manufactured. This involves machining, welding, and fabrication processes. Components are inspected to ensure they meet the specified tolerances and quality standards.

Assembly

Purpose: Put together the machine.

Process: The manufactured components are assembled according to the design specifications. This includes mechanical assembly, installation of pneumatic or hydraulic systems, and integration of electrical and control systems.

Integration and Testing

Purpose: Ensure all systems work together seamlessly.

Process: The assembled machine is integrated with control systems and tested for operational functionality. This includes software installation, calibration of sensors and actuators, and ensuring the machine operates as intended.

Final Adjustments and Quality Assurance

Purpose: Fine-tune the machine and ensure quality.

Process: Any necessary adjustments are made to optimize performance. The machine undergoes rigorous quality assurance tests to ensure it meets all design specifications and operational standards.

Customer Acceptance Testing

Purpose: Confirm the machine meets customer requirements.

Process: The customer is invited to test the machine under real-world conditions. Any issues identified during this phase are addressed before final delivery.

Global Impact:

Through strategic negotiations with major clients, XINTU Automation has forged valuable partnerships and alliances, significantly boosting our global presence. Our dedicated team of experts has expanded to include 10 top-tier executives who continuously nurture new talent to scale our operations and meet the growing demands of the global market.

XINTU’s dedication to quality and innovation has earned us a reputation for excellence. Our machines are designed to be fully automatic and customizable, providing solutions that meet the specific needs of each client. This has resulted in long-term partnerships with medium to large-scale manufacturers, trade companies, and industrial automation firms.

Choose XINTU for a partnership that delivers exceptional results and fosters growth on a global scale.

OUR TEAM

The Experts Behind Our Success

Mary Ma-Overseas Project Manager

Mary Ma is dedicated to fostering genuine communication with clients, always considering their perspective. She specializes in providing quick and simple solutions to client issues and recommends the most suitable automatic case packers based on actual client needs.With a majoy in international business, Mary brings a wealth of knowledge and expertise to her role at XINTU.

In her personal life, Mary enjoys a variety of activities that keep her balanced and motivated. She loves traveling to explore new cultures, taking leisurely walks, swimming, skiing, singing, and watching English movies. These hobbies not only enrich her life but also help her connect with clients from diverse backgrounds, making her an effective and empathetic project manager.

Jack Wang-Cheif Engineer

Jack Wang has been passionate about physics and mechanical design since middle school. He is known for his innovative ideas in design and his ability to solve industrial challenges swiftly. Proficient in CAD and 3D software, Jack customizes the most suitable end-of-line packaging machines for clients, constantly pushing the boundaries in developing the latest packaging lines. His expertise ensures that every case packing solution is tailored to meet the unique needs of each customer, optimizing efficiency and performance.

In his personal life, Jack enjoys traveling, engaging in various sports, singing, watching movies, and going on road trips. These activities fuel his creativity and provide a well-rounded perspective that enhances his professional endeavors. Jack’s dedication to both his work and hobbies makes him a dynamic and innovative leader in the field of packaging machinery.

William Li-Production Manager

William Li has had a passion for building blocks and assembling various mechanical models since high school. With strong logical thinking skills, he quickly grasps mechanical structures and assembles them efficiently. Both in his personal life and at work, William is meticulous and pays close attention to every detail, ensuring precision and quality in everything he does.

In his spare time, William enjoys fishing, playing chess, traveling, engaging in sports, and playing the guitar. His diverse interests not only fuel his creativity but also enhance his problem-solving skills, making him an adept and reliable leader in production management. William’s commitment to excellence and his detail-oriented approach make him an invaluable asset to our team.

MOST FREQUENTLY ASKED QUESTIONS AND ANSWERS

FAQ

Packaging Machines Details

How do your case packing machines ensure high precision and reliability?

Our case packing machines utilize advanced servo motors and precise control systems to guarantee high precision and reliability. This ensures consistent performance, minimal downtime, and accurate packaging for all types of products.

What makes your robotic palletizers efficient for large-scale operations?

Our robotic palletizers are equipped with state-of-the-art sensors and AI-driven algorithms that optimize palletizing patterns, speed, and accuracy. They can handle a wide range of product sizes and weights, making them ideal for large-scale operations.

Why choose customized case packaging lines from XINTU?

Our customized case packaging lines are tailored to meet your specific needs, ensuring seamless integration with your existing production lines. They offer flexibility, high efficiency, and can be adapted to handle various packaging formats and materials.

Production and Delivery Process

How long does it take to receive a custom packaging solution from XINTU?

The lead time for a custom packaging solution varies based on the complexity of the project. Standard solutions are typically delivered within 35 business days, while highly customized projects may take longer depending on specific requirements and production schedules.

How long does the testing phase take after production is complete?

The testing phase for our machines typically takes between 5 to 15 business days, depending on the complexity of the equipment and the specific requirements of the project. This ensures that each machine meets our high standards for quality and performance before being delivered to the customer.

How do you ensure timely delivery of your machines?

We have a streamlined production process and a robust supply chain network that allows us to adhere to strict delivery timelines. Our project management team keeps you informed at every stage to ensure timely and efficient delivery.

After Sales Support

What kind of after-sales support does XINTU provide?

XINTU provides lifetime technical support, a 12 months spare parts warranty, and regular maintenance services. Our support team is always available to assist with any issues or questions you may have.

How do you handle service requests or troubleshooting?

Service requests can be made through our dedicated support portal or via email. Our technical team responds promptly to troubleshoot issues and provide solutions, ensuring minimal disruption to your operations.

What training do you offer for machine operators?

We offer comprehensive training programs that include on-site training, online tutorials, operation videos,and detailed user manuals. This ensures your operators are fully equipped to handle the machines efficiently and safely.